Standard press brake tools serve most basic bending needs. However, as sheet metal parts become more complex—featuring tighter angles, overlapping features, or recessed areas—relying on conventional punches and dies becomes inefficient and limiting. That’s where specialized press brake tooling comes in. With the right press brake tools, manufacturers can form intricate geometries, speed up production, and improve final part quality. Anhui Tooling, a trusted name in high-performance specialized press brake tooling, offers a wide range of custom solutions tailored to these demanding tasks.

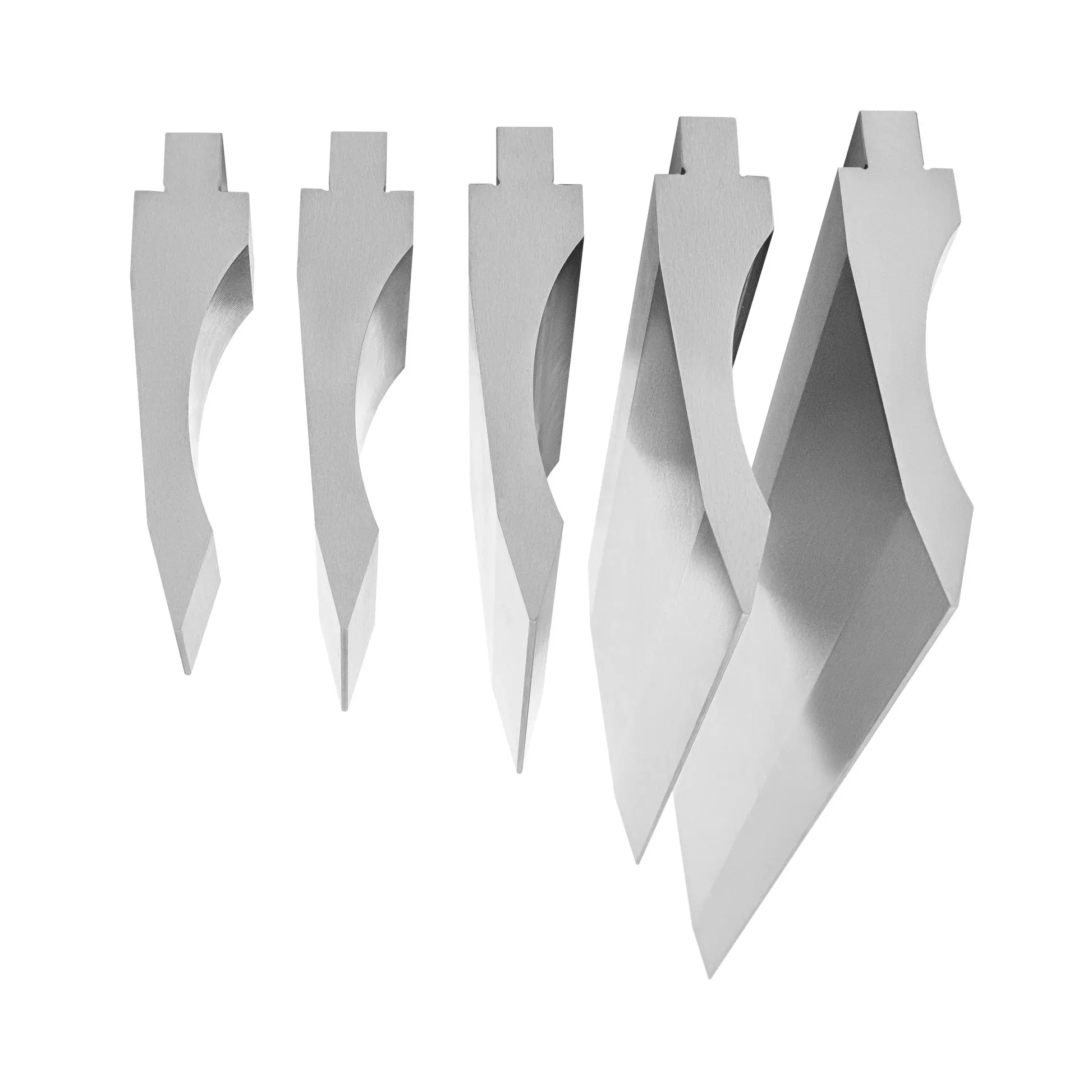

Acute Angle Punch – Precision Bending Below 90°

When your design calls for a bend tighter than 90 degrees, the acute angle punch becomes essential. With a sharp punch tip, usually between 30° and 60°, this tooling enables clean, consistent bends for components such as brackets, decorative profiles, or narrow channels. It is particularly effective in air bending and bottom bending applications across electronics, appliance housing, and metal furniture industries. Anhui Tooling manufactures acute punches with excellent tip accuracy and wear resistance, ensuring consistent performance even in high-throughput environments.

Sash Press Brake Punch – Narrow Profile Tooling for Deep and Confined Forms

Some profiles, especially in window frames and architectural components, involve tight spaces that traditional tools simply can’t reach. The sash punch, also known as a window punch, solves this problem with a slim, extended design. It can access narrow cavities or deep flanges without interference. This makes it ideal for bending internal window frames, recessed channels, or parts that require clearance for upward flanges. Anhui Tooling offers sash punches designed to minimize tool deflection while maintaining bending precision.

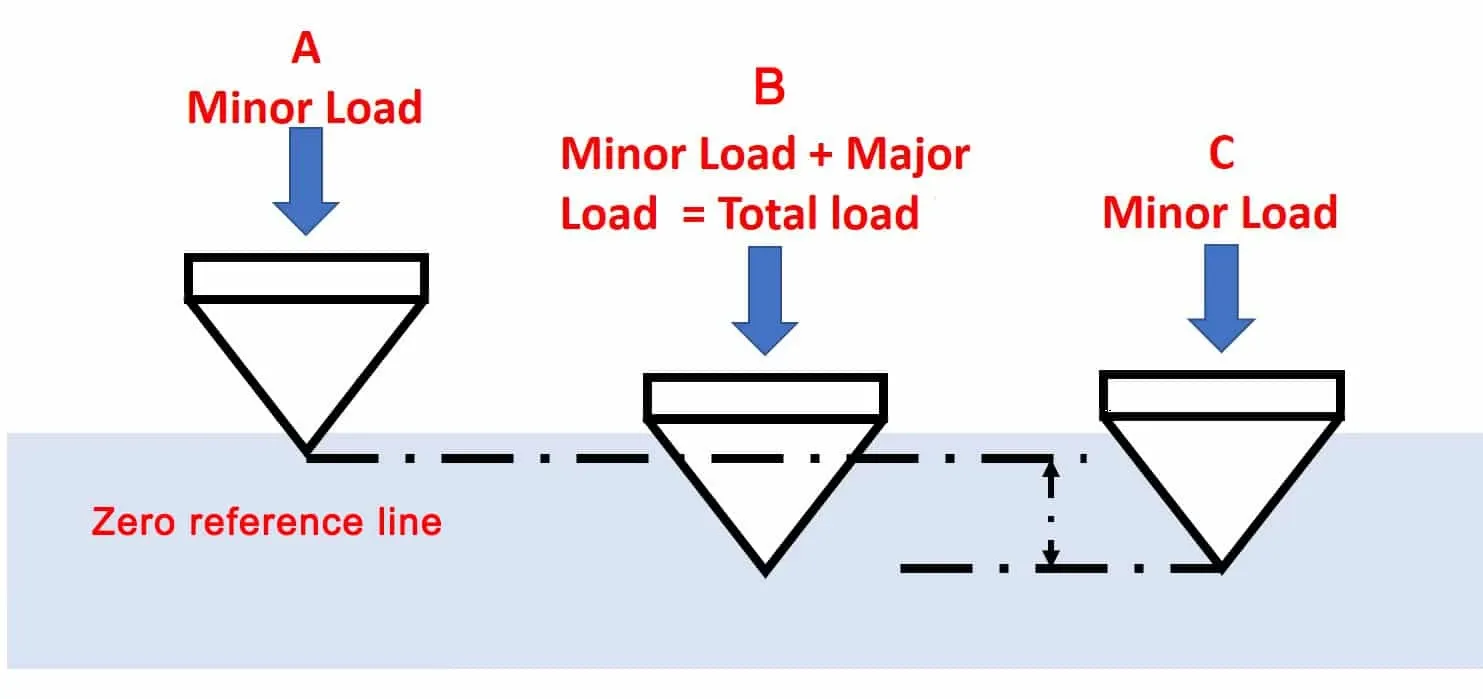

Offset Forming Punch – One-Step Z-Shape Forming

Offset Forming Punch – One-Step Z-Shape Forming

Z-bends usually require two bending operations—but not with an offset forming punch. This specialized tool allows fabricators to create an offset (Z-shape) in a single stroke, eliminating repositioning and reducing handling time. Offset tooling is often used in electrical enclosures, mounting brackets, clips, and structural supports. Anhui Tooling provides both standard and custom offset punches that support a wide range of offset depths, helping manufacturers improve throughput without compromising accuracy.

Radius Top Tooling – Smoother Bends with Less Stress

Bending with a large internal radius is often necessary to prevent material cracking or surface deformation—especially when working with high-strength steel, aluminum, or pre-coated metals. Radius top tooling creates a generous bend radius, minimizing stress concentration and springback. This tooling is widely used in aerospace, transportation, and high-end furniture manufacturing. Anhui Tooling offers radius punches with variable radii to match different material types and reduce edge fatigue, supporting both functional and aesthetic requirements.

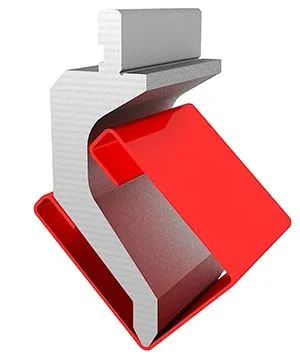

Joggle Press Brake Tooling – Efficient S-Shape Forming for Overlapping Components

An S-shaped offset, or “joggle,” is a common feature in aerospace and HVAC sheet metal assemblies. It allows one sheet to sit flush over another, improving fitment and structural continuity. Joggle tooling typically includes matched male and female dies, available in various offset sizes. Anhui Tooling engineers these tools for precision, repeatability, and long-term use, making them ideal for high-volume production of panels, ducts, and nested assemblies.

Segmented Press Brake Dies – Flexible Forming for Irregular Part Geometries

When working with parts that have cutouts, uneven edges, or multiple bend zones, fixed-length dies can be cumbersome. Segmented dies—modular tooling sets that can be rearranged as needed—solve this problem. They’re ideal for producing cabinets, complex panel designs, or variable-length components. With segmented dies from Anhui Tooling, operators can quickly adapt tooling setups without investing in numerous fixed configurations, saving both time and cost.

Gooseneck Punches – Ideal for Bending with Return Flanges

Although common, gooseneck punches are essential for forming parts that include return flanges. Their unique profile allows them to clear existing flanges during secondary bends, avoiding collisions and maintaining part integrity. Gooseneck punches are frequently used in electrical cabinets, toolboxes, and box-type enclosures. Anhui Tooling offers robust, high-clearance gooseneck punches compatible with various clamping systems, ensuring accurate and collision-free bending across a wide range of applications.

Choosing the Right Special Tooling

Before investing in specialized tooling, fabricators should consider several factors. Part geometry, flange depth, material type, and press brake compatibility all influence tooling selection. Thicker or harder materials require strong, wear-resistant tools, while tight-tolerance parts demand precision-ground profiles. Anhui Tooling’s engineering team works closely with manufacturers to deliver tailored solutions—balancing durability, dimensional accuracy, and machine fitment.

Why Choose Anhui Tooling?

Anhui Tooling has established itself as a reliable supplier of both standard and custom press brake tools. With modern CNC machining equipment, strict quality control, and deep expertise in tool steel treatment, they are able to produce high-performance tools that meet the demands of today’s most advanced forming operations. Whether you require acute bends, joggles, or Z-shapes, Anhui Tooling’s product lineup ensures consistent, cost-effective results.

Conclusion

Specialized press brake tooling is not just for niche applications—it’s a smart investment for any manufacturer aiming to produce more complex parts, reduce setup times, and boost bending efficiency. Tools like acute angle punches, offset punches, sash punches, and joggle tooling make it possible to tackle designs that standard punches can’t accommodate. With a trusted partner like Anhui Tooling, fabricators can equip their press brakes to meet evolving production demands with precision and reliability.