When it comes to press brake operations, achieving precise bends and cuts in metal components is crucial. The role of press brake die holders often goes overlooked, but these components are essential for ensuring that tooling is set up securely and accurately. Today I gonna veil the importance of press brake die holders, their types, and how they contribute to improved production efficiency and safety.

What Is a Press Brake Die Holder?

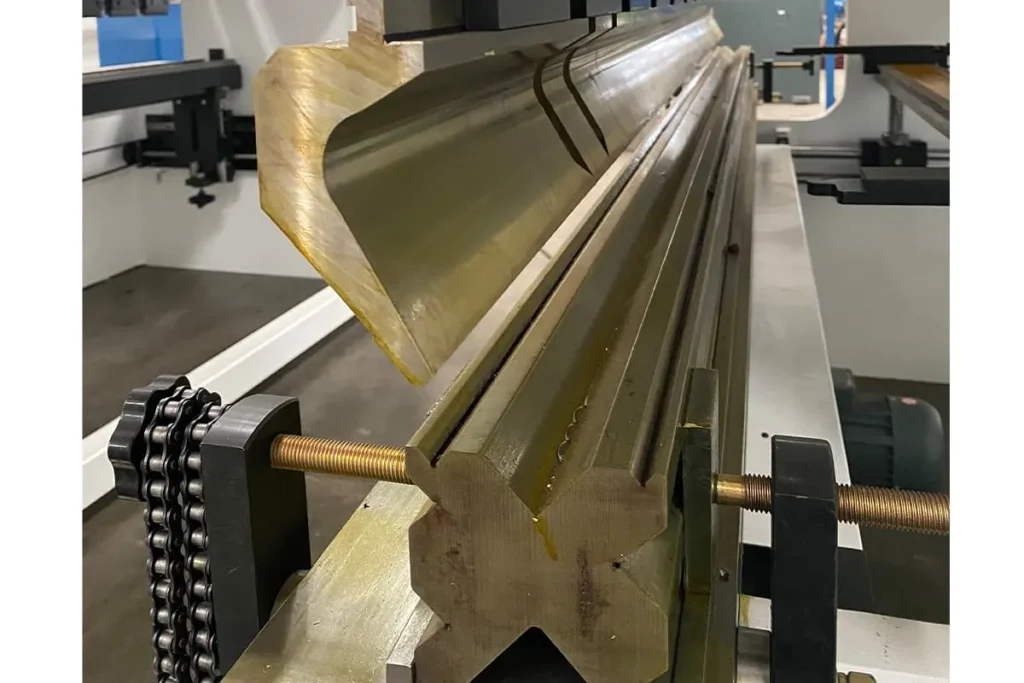

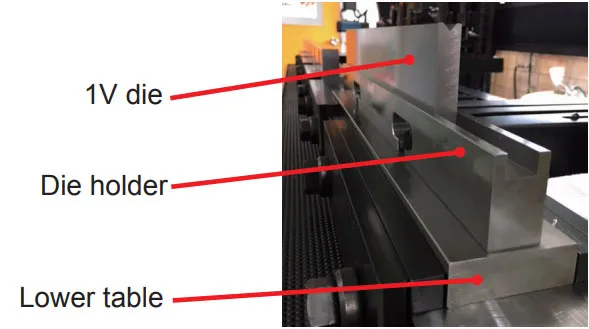

A press brake die holder is a crucial component of the tooling setup on a press brake machine. Essentially, it is the device that holds and supports the dies during bending operations. Its primary function is to ensure the dies are securely positioned and aligned, which directly affects the accuracy of each bend and cut. Without a proper die holder, tool setup can become unstable, resulting in defects and inaccuracies.

The die holder also plays a safety role. A well-secured die minimizes the chances of it becoming dislodged during operation, which could lead to costly mistakes or even safety hazards for the operators. Therefore, die holders are designed with precise fitment and locking mechanisms to support tooling accuracy and safety during every operation.

Types of Press Brake Die Holders

Not all press brake die holders are the same. Different types of holders cater to various machine models and operational needs. Understanding the types of press brake die holders available can help you select the best one for your press brake setup.

Conventional Die Holders

Conventional die holders are the most common type used in traditional press brake machines. These holders are often adjustable to fit a wide range of dies, making them self-centering for general-purpose applications. However, they can only handle specific condition and problem, usually not suitable when bending tasks require between different press brake dies.

European Die Holders

European-style die holders, typically found in European-made press brakes, are designed with a more streamlined locking mechanism. These holders offer precise positioning and can accommodate heavier dies, which are ideal for high-load applications. The European design focuses on pneumatic construction and ease of use, ensuring minimal vibration and maximum accuracy during operations.

Four-Way Die Holders|

Four-way die holders are specific tools that allow four different direction of die setups in one holder, optimizing space and reducing the time needed for die changes. This is especially useful in high-volume production environments where multiple dies are needed for various bending tasks. The ability to use four dies in one holder increases production flexibility and helps maintain high operational efficiency.

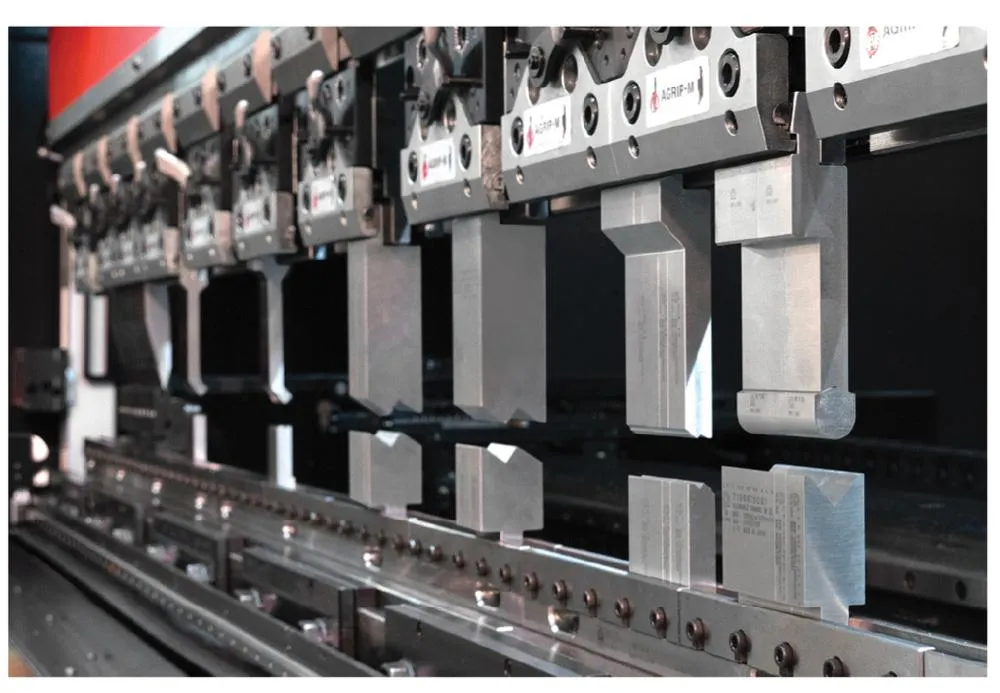

Trumpf-Wila Die Holders

Trumpf-Wila die holders are engineered for specific use with Trumpf press brake machines. These holders provide quick and secure die positioning with precise alignment. They are especially designed to integrate seamlessly with Trumpf systems, offering enhanced accuracy and speed during the setup process. Wila die holders are known for their innovative designs, which allow quick die changeovers with minimal downtime.

Press Brake Die Holders and Tooling Changeover

Tooling changeover is an essential part of press brake operations, especially in environments where high flexibility is required. This is where die holders truly shine. By using specialized die holders, such as quick-release or automatic locking systems, operators can change dies in a fraction of the time it would take with conventional methods.

Quick-release die holders, for example, allow operators to swap out tooling with minimal effort, reducing downtime and increasing productivity. When die changes are streamlined, it minimizes interruptions to production, leading to faster turnaround times and more efficient operations. For industries that require frequent die changes for different projects, investing in quick-change die holders is a great way to reduce costs and improve operational efficiency.

Selecting the Right Die Holder for Your Press Brake

Choosing the right die holder for your press brake is crucial for ensuring optimal performance. Several factors should be considered before making a selection:

Machine Specifications: It’s essential to choose a die holder that matches the specifications of your press brake. This includes ensuring that the die holder fits securely into the machine and can support the required tonnage.

Die Compatibility: Not all die holders will work with every type of die. Be sure to select a die holder that is compatible with the specific dies you plan to use. The compatibility between the holder and die ensures proper alignment, enhancing precision and safety.

Project Requirements: Consider the types of materials and bending applications you will be working with. For heavier-duty applications, opt for more robust die holders that can handle higher loads and provide greater accuracy.

By taking these factors into account, you can ensure that the die holder you choose will contribute to improved precision, safety, and efficiency in your press brake operations.

Conclusion

Press brake die holders are more than just simple components—they are vital for ensuring secure and accurate tooling setup. With the right die holder, you can improve the efficiency of tooling changeovers, minimize downtime, and enhance the overall precision of your press brake operations. By understanding the different types of die holders available and selecting the one that best suits your needs, you can optimize your press brake machine for maximum productivity and reliability.

Investing in high-quality die holders is not only an investment in your equipment but also in the overall efficiency and success of your production line. Make the right choice today to enhance your press brake operations and take your production efficiency to the next level.