Introduction

When it comes to metal sheet fabrication, efficiency, accuracy, and tooling flexibility are critical factors in maintaining competitive performance. One of the most noticeable shifts in recent years is the growing adoption of European style press brake tooling across fabrication shops worldwide. Known for its precision design, user-friendly setup, and compatibility with modern press brake technology, European press brake tooling has become a preferred choice for many manufacturers. This blog is about what defines this tooling system, why it’s gaining popularity, and how it supports advanced metal forming applications.

What Defines European Style Press Brake Tooling?

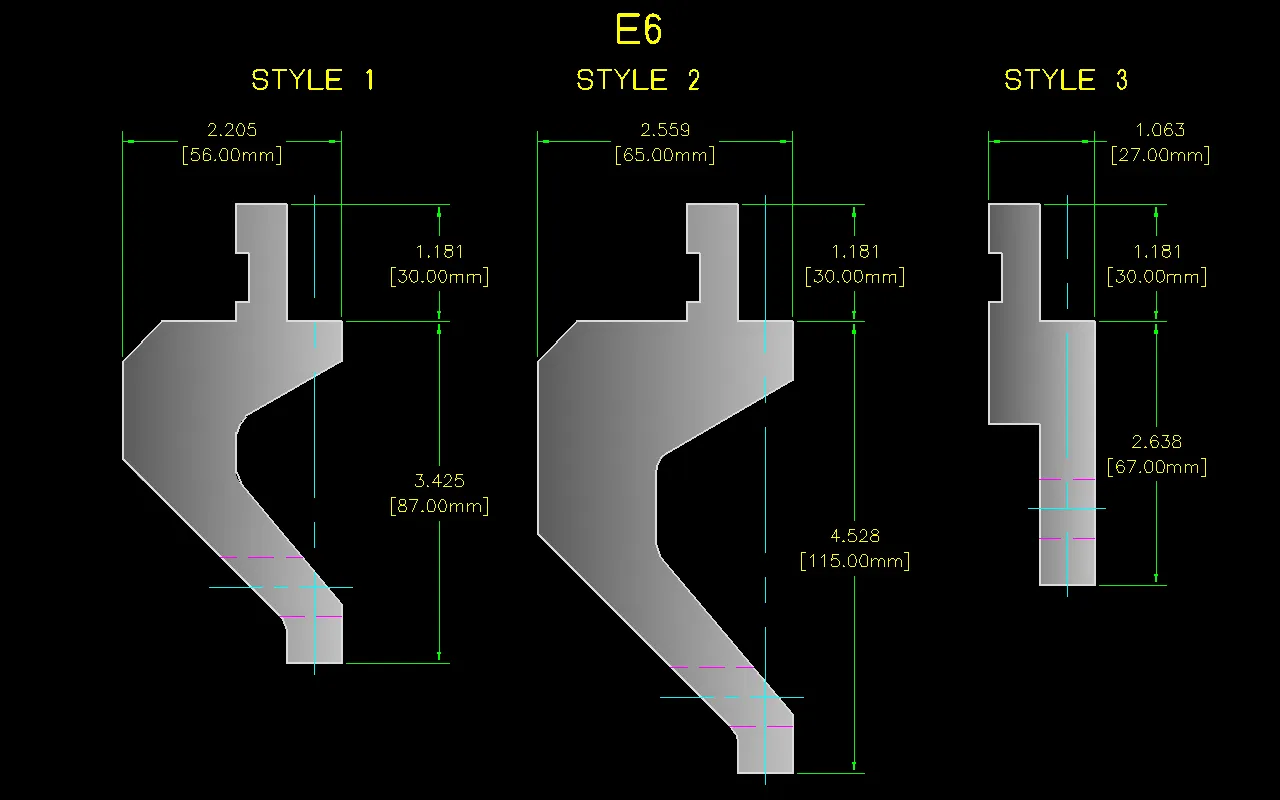

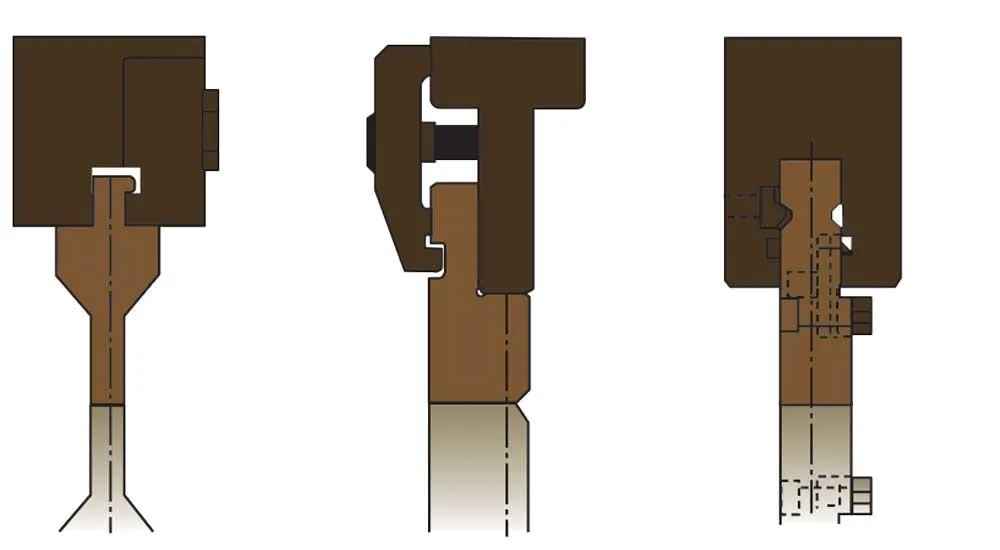

European style press brake tooling refers to a specific standard of punch and die tooling widely used across Europe and now gaining ground globally. Unlike American-style tooling, which features a larger tang and pin-based locking system, European tooling uses a narrower tang and often incorporates a dovetail or clamping mechanism for easy setup and alignment. The tooling is generally modular, allowing fabricators to switch out segments quickly to accommodate a range of part sizes and shapes.

One of the main differences is in the mounting style and tool geometry. European punches typically have a smaller footprint and are designed for quick clamping systems, making them ideal for high-mix, low-volume production. The dies are also narrower, enabling tighter bend radii and closer flange work. These characteristics make European press brake tooling especially attractive for fabricators who demand fast changeovers and high accuracy.

Furthermore, many modern CNC press brake machines—especially those manufactured in Europe or Asia—are designed specifically to accommodate European-style tooling. This growing compatibility, along with advancements in automated tool changers, has contributed to the widespread adoption of the European tooling system.

Advantages of European Press Brake Tooling

The rising preference for European press brake tooling is not just a trend—it’s rooted in tangible advantages that improve workflow, precision, and long-term tool maintenance.

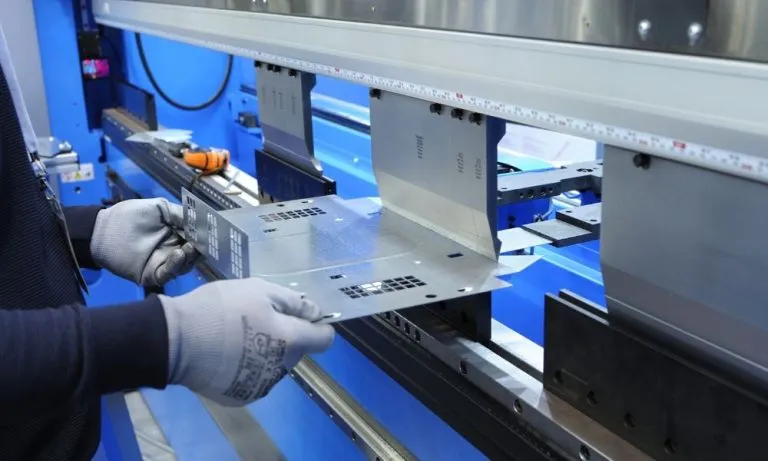

One major benefit is the lightweight and ergonomic design of European-style tools. Compared to their American counterparts, European punches and dies are typically shorter and lighter, making them easier and safer to handle during tool changeovers. This ease of use not only enhances operator productivity but also reduces the risk of injury in high-turnover environments.

Another significant advantage is ease of installation and alignment. Thanks to the standardization of tool dimensions and the incorporation of self-seating mechanisms, European tools can be installed quickly and with minimal adjustment. This feature is particularly valuable in lean manufacturing environments where minimizing downtime is crucial.

Precision is another strong point. European tools are manufactured to tight tolerances and designed to sit accurately in the press brake ram and bed, ensuring consistent bend angles and reducing the need for rework. This level of accuracy also helps extend the life of both the tooling and the machine itself by minimizing misalignment-related stress and wear.

Lastly, compatibility with automation is a growing advantage. Many modern press brakes are equipped with automated tool changers that are specifically designed for European-style tooling. This integration further reduces changeover time and allows for seamless transitions between jobs in automated production lines.

The benefits of European style press brake tooling translate directly into performance in a wide range of industries. It is particularly well-suited for high-precision, short-run production—making it a favorite in sectors such as aerospace, electronics, automotive, and custom metal fabrication.

For example, in the aerospace industry, where tight tolerances and lightweight parts are critical, European tooling enables precise forming with minimal waste. In automotive production, rapid tool changeovers are essential to meet just-in-time manufacturing requirements, and the modular nature of European tools facilitates this efficiency.

Architectural metalwork and signage manufacturers also benefit from European tooling’s flexibility, especially when producing parts with complex geometries and varied bend angles. Likewise, in HVAC and enclosure manufacturing, European press brake tooling offers the advantage of forming narrow flanges and intricate bends without needing to reposition the material excessively.

Overall, any application that values accuracy, flexibility, and quick setup can benefit significantly from the adoption of European-style tooling.

Choose the Right European Style Tooling for Your Press Brake

Transitioning to European press brake tooling requires thoughtful consideration to ensure seamless integration and maximum benefit. One of the most important factors is machine compatibility. Not all press brakes are designed to accept European-style punches and dies by default. However, retrofit kits and adapters are available to convert many machines originally configured for American tooling.

When selecting tooling, fabricators should consider the material type, thickness, and required bend radius. European tooling comes in a variety of profiles, coatings, and hardness levels to suit different materials, including stainless steel, aluminum, and galvanized steel.

Another key consideration is the clamping system. For shops aiming to improve efficiency, investing in press brakes equipped with quick-change clamping systems—such as hydraulic or pneumatic clamps designed for European tooling—can dramatically reduce setup times.

It’s also important to source tooling from reputable manufacturers who provide precision-ground tools with certified hardness and tolerance levels. For example, Anhuitooling offers a full range of European style press brake tooling engineered to deliver long life, precise performance, and seamless compatibility with modern press brake systems.

Conclusion

European style press brake tooling represents a smart evolution in metal forming technology, offering clear advantages in terms of accuracy, ease of use, and modern machine compatibility. Whether you’re a small shop seeking faster setups or a large manufacturer requiring tight tolerances across thousands of parts, European press brake tooling offers a solution that aligns with today’s production demands. As fabrication challenges continue to grow more complex, investing in high-quality European tooling can help you stay ahead of the curve and elevate the performance of your press brake operations.