Sheet metal fabricators know that successful bending isn’t just about the press brake—it’s about the tooling. When you’re working with steel, aluminum, and copper, each metal behaves differently under stress.

Different metals react very differently to bending forces. Whether you’re working with steel, aluminum, or copper, selecting the right press brake tooling is essential to ensure consistent bend angles, surface quality, and long tool life. Using the right punch, die, hardness, R-angle, V-die opening, and surface finish directly influences part quality, tool longevity, and overall productivity.

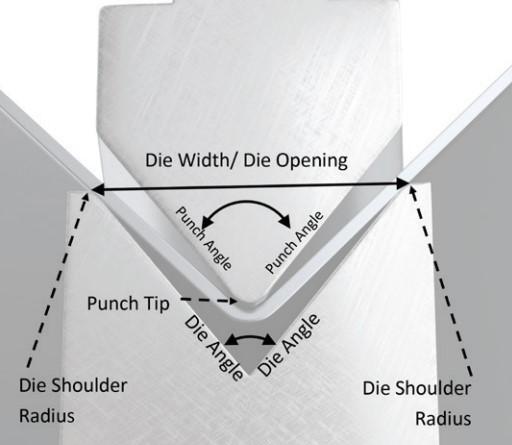

R-Angle & V-Die Sizing in Metal Bending

To achieve precise and reliable bends, it’s important to follow certain tooling selection rules:

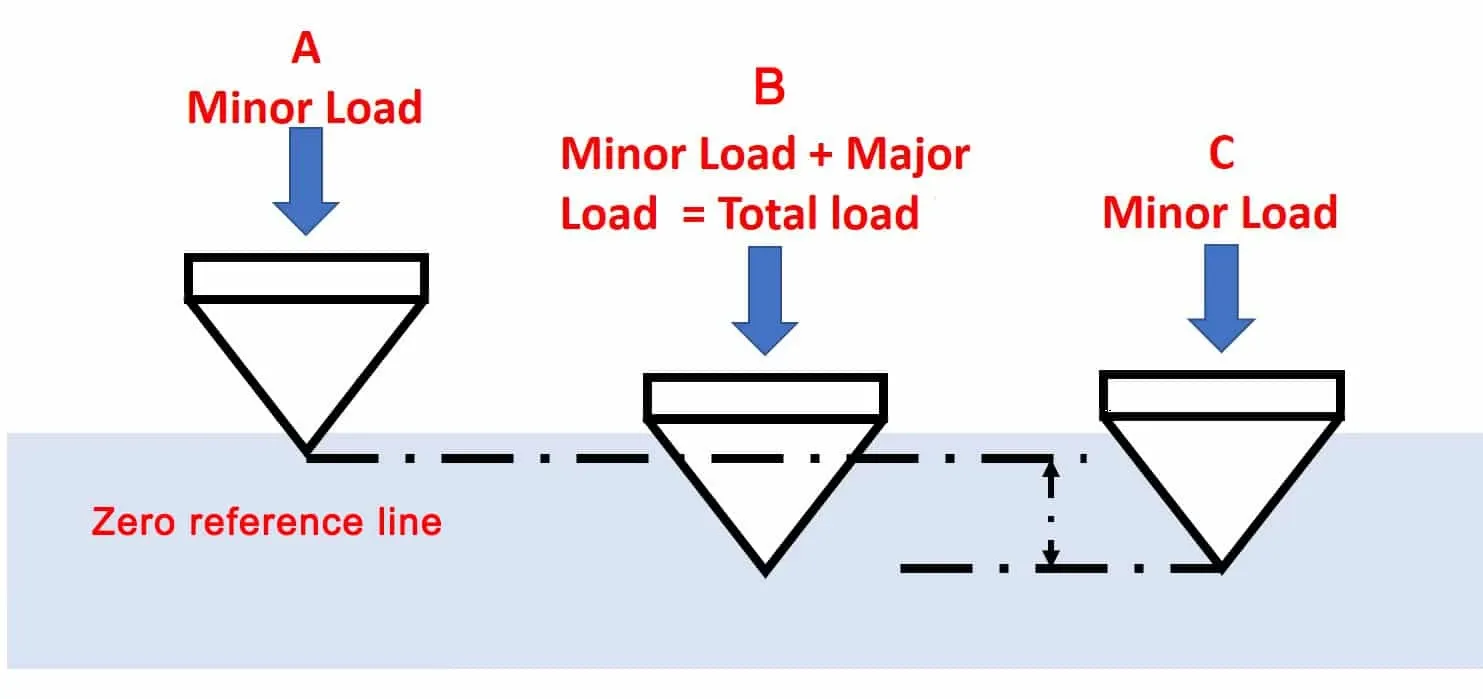

The V-die opening (V) is typically 8 times the sheet thickness (S).

A key rule: set the die opening (V) around 8× the sheet thickness (S)

The internal radius (R) of the die should be approximately 16% of the V-opening.

Standard tooling angles such as 88° or 86° are used, with common punch radii including R0.2 mm for sharp bends and R0.6 mm for general applications.

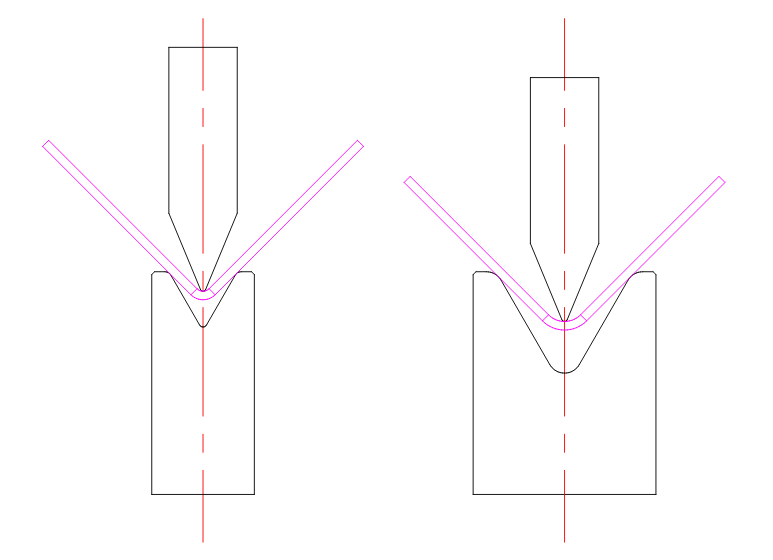

These principles apply to most material types but need to be adjusted according to the metal’s hardness, springback tendency, and surface sensitivity.

From then on, it’s bout to unfold by how to choose targeted press brake tooling for each specific metal bending, including steel bending tooling;aluminum bending tooling and copper bending tooling.

Steel Bending: High Strength and High Springback

Steel is the most common material used in bending operations and presents unique challenges due to its high tensile strength and springback.

Characteristics AFFECT Bending:

- High hardness and strength

- Significant springback after bending

- May cause accelerated wear on tooling

Steel Bending Press Brake Tooling Suggestion::

Material: Use tooling made from C45 or 42CrMo hardened to HRC45–50.

V-die opening: For 2 mm thick steel, use V16 mm.

Internal Radius (R): Should be around 2.5 mm.

Punches: Opt for punches with R0.6 mm or larger depending on the desired bend radius.

Anhui Tooling offers European-style segmented punches and dies in 42CrMo, hardened and precision-ground for heavy-duty steel bending. These tools ensure dimensional accuracy and resistance to wear, perfect for frequent operations on carbon or stainless steel sheets.

Aluminum Bending: Soft, Ductile, but Prone to Marking

Aluminum is lightweight and easy to bend, but its softness makes it vulnerable to surface damage and cracking if not handled with care.

Characteristics AFFECT Bending:

- Lower strength than steel

- Low springback

- Sensitive to scratches and tool marks

Aluminum Bending Press Brake Tooling Suggestion:

Use highly polished C45 or 42CrMo tools to prevent scratching.

V-die opening: Between 6× and 12× the sheet thickness; typically 8× is ideal.

Internal Radius (R): Keep small, such as R0.2 mm, for precision folds.

Optional Coatings: TiN or PTFE coatings reduce marking and improve surface quality.

For aluminum, Anhui Tooling recommends segmented European-style punches with R0.2 mm tips and polished surfaces. Roller V-dies are also available to reduce friction and eliminate surface damage during bending.

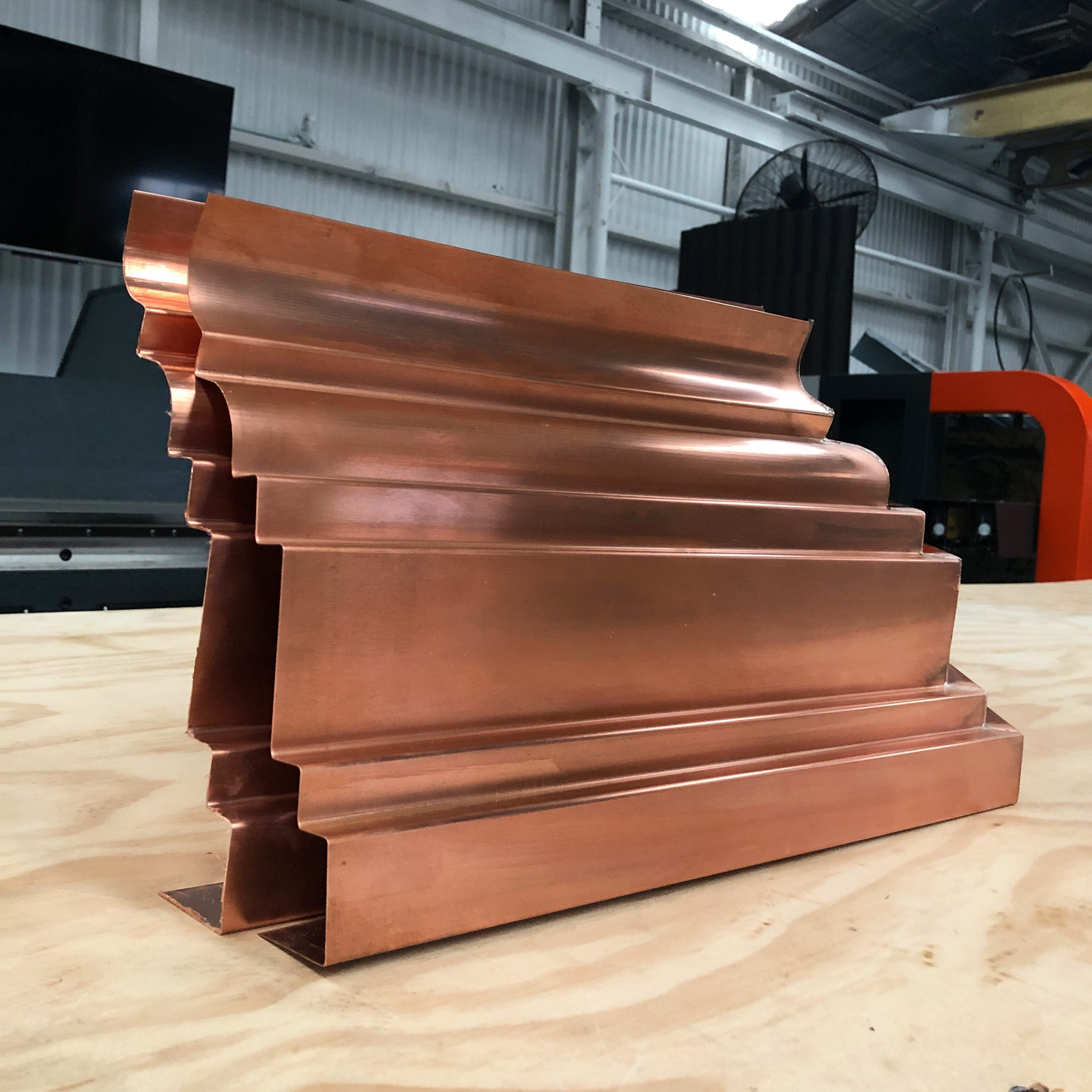

Copper Bending: Soft but Demanding

Copper is highly malleable and excellent for electrical applications, but its softness also means it’s easily marked or distorted during bending.

Characteristics AFFECT Bending:

- Excellent ductility

- Very sensitive to surface scratches

- Can stick to uncoated tools due to high friction

Copper Bending Press Brake Tooling Suggestion:

Use hardened tools (HRC45–50) with mirror finishes.

V-die opening: Follow the 8× thickness rule.

Internal Radius (R): Preferably R0.2 mm or less for fine folds.

Optional Coatings: DLC coatings help prevent galling and sticking.

Anhui Tooling provides R0.2 mm radius punches with polished or coated surfaces, perfect for precision copper work. These are often used in industries where electrical conductivity and cosmetic finish are critical.

Customization Capabilities at Anhui Tooling

Anhui Tooling specializes in manufacturing press brake tooling in various styles and configurations. Standard options include:

Tool Materials: C45 and 42CrMo, hardened to HRC45–50 for durability and toughness.

Punch Radii: Available from R0.2 mm to R2 mm and beyond.

V-die Openings: Ranging from V4 to V120, covering thin to thick metal bending applications.

Lengths: Full-length (835 mm), sectional, and custom lengths to fit different press brakes.

Compatibility: European, Amada, Trumpf, Wila, LVD, and other international tooling systems.

These tools are available with optional coatings such as TiN or DLC, as well as with roller dies for scratch-sensitive metals like aluminum and copper.

A Quick Table of Specific Press Brake Tooling For Different Metal Bending

| Material | Sheet Thickness | V-Die (≈8× S) | Punch R | Die R (≈16% of V) | Surface Treatment |

| Steel | 2 mm | V16 mm | R0.6 mm | 2.5 mm | Ground finish |

| Aluminum | 1.5 mm | V12 mm | R0.2 mm | 2 mm | Polished / TiN |

| Copper | 1 mm | V8 mm | R0.2 mm | 1.3 mm | DLC coated |

These combinations deliver smooth bends, prevent over-straining the material, and ensure long service life for the tooling.

Why Choose Anhui Tooling For Your Bending?

Advanced Materials: All punches and dies are made from C45 or 42CrMo, heat-treated for long service life.

Precision Engineering: Machined to strict tolerances, ensuring accurate and consistent bends.

Wide Compatibility: Full range of styles compatible with most global press brake brands.

Custom Solutions: Custom punch tips, angles, R-values, V-die widths, and lengths are available upon request.

Support & Service: Anhui Tooling supports bulk orders, fast delivery, and technical guidance for selecting the right tooling for your application.

Conclusion

Each metal—steel, aluminum, and copper—demands unique consideration during the bending process. With the right tooling, fabricators can ensure precision, reduce waste, and extend tool life. Anhui Tooling offers the expertise, materials, and customization capabilities needed to meet the demands of various metals and applications.

If you’re looking for reliable, accurate, and high-performance press brake tooling, Anhui Tooling is ready to help. Contact our technical team to find or design the ideal solution for your next bending project.