When it comes to precision metal bending, selecting the right tooling is crucial for efficiency, quality, and cost-effectiveness. For sheet metal fabricators, auto manufacturing manufacturers, and appliance producers, press brake dies are the backbone of production. Among the most commonly discussed options are press brake hemming dies and 4 way press brake dies. Understanding their differences, applications, and interrelation can significantly improve your bending operations.

Anhui Tooling, a leading Chinese manufacturer of high-quality press brake dies, will walk you through these two die types in detail, helping you make an informed choice for your production line.

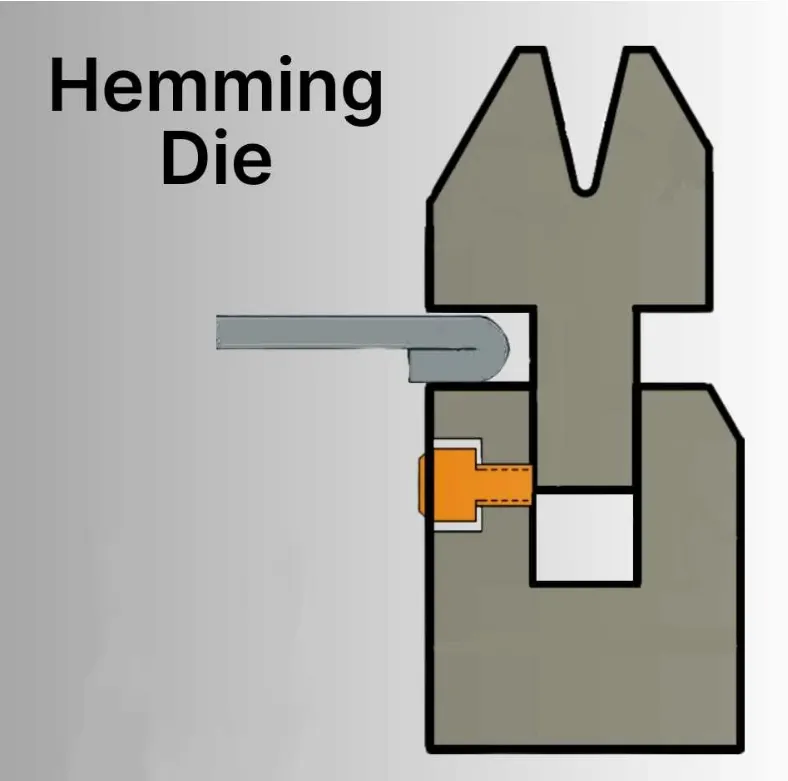

What Are Press Brake Hemming Dies?

Press brake hemming dies are specialized tools designed to perform hemming operations—a process where sheet metal edges are folded over themselves to create smooth, safe, and reinforced edges. Hemming is widely used in the auto manufacturing industry for car doors, hoods, and trunk panels, as well as in home appliances and aerospace applications.

Key Features of Hemming Dies

Precision Folding: Hemming dies are engineered for high-accuracy bends, typically up to 180 degrees, ensuring a tight and uniform fold.

Edge Protection: By folding sheet edges, hemming reduces sharpness, enhancing safety and improving product aesthetics.

Material Compatibility: High-strength steel or aluminum sheets can be folded without cracking or deformation.

Specialized Structure Design: Hemming dies are usually custom-designed to match the specific bend radius and profile of a product.

Applications

Auto manufacturing body panels

Appliance housings and enclosures

Aerospace sheet metal components

Furniture and metal fixtures requiring safe, rounded edges

Hemming dies are indispensable when product quality and edge appearance are paramount.

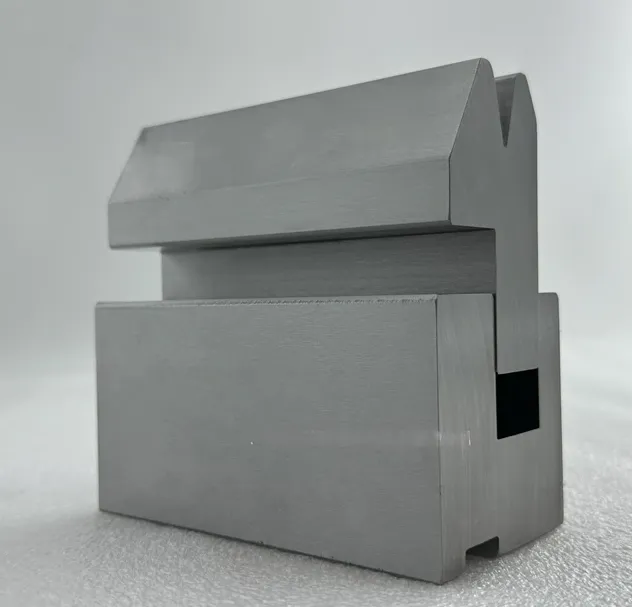

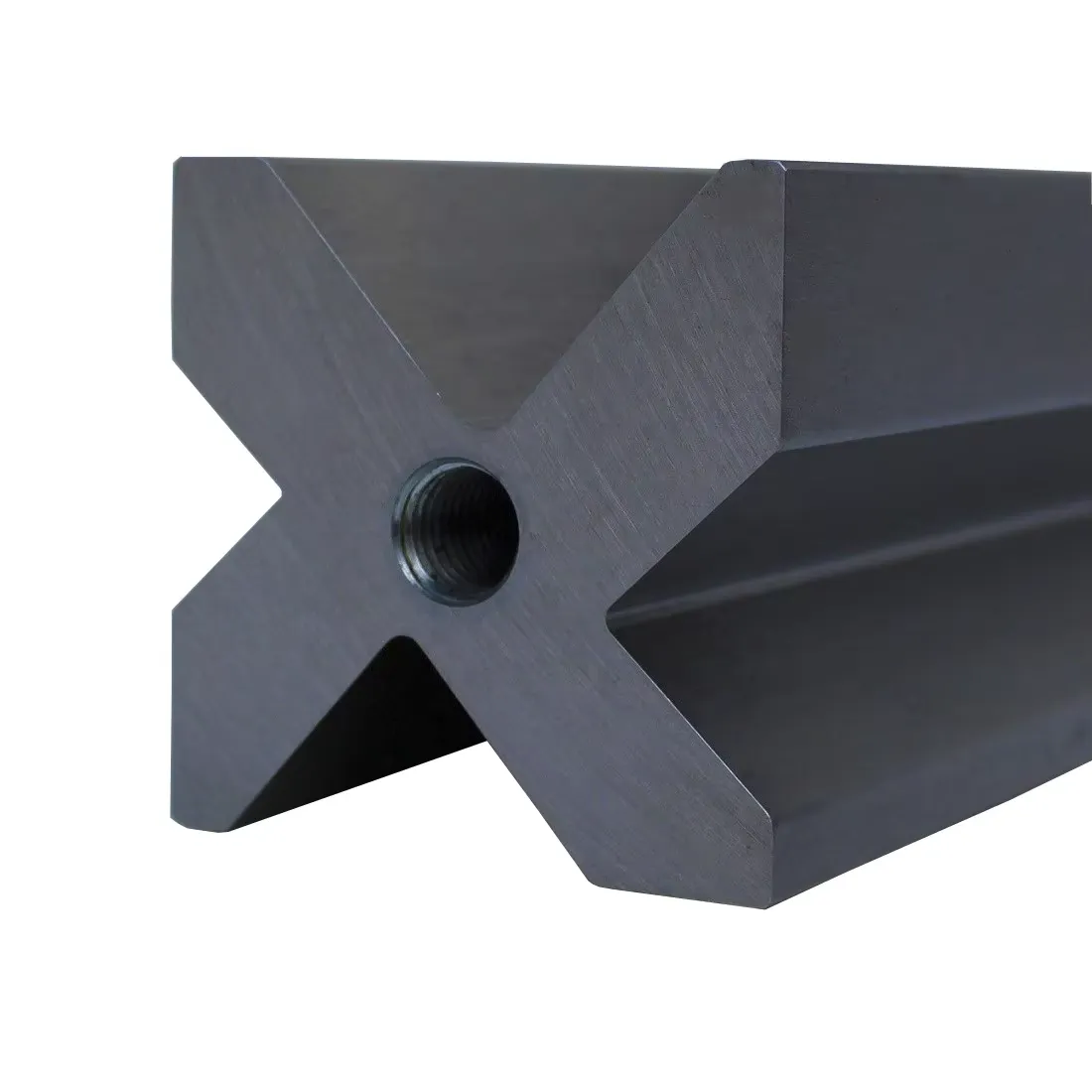

What Are 4 Way Press Brake Dies?

While press brake hemming dies serve a specialized purpose, 4 way press brake dies provide versatility and multi-functionality. As the name implies, a 4-way die can perform four distinct bending operations, usually including V-bending, U-bending, hemming, and sometimes deep drawing or special forming.

Features of 4 Way Dies

Multi-Functionality: One die can handle multiple bending tasks, reducing the need for frequent die changes.

Time Efficiency: Minimizes downtime on production lines by offering various bending capabilities in a single setup.

Rotatable or Modular Design: Many 4-way dies are designed to rotate or be adjusted to switch between operations quickly.

Cost Savings: Instead of buying multiple dedicated dies, manufacturers can invest in a single 4-way die for different bending needs.

Applications

Small to medium-batch production lines

Facilities requiring multiple bending operations in quick succession

Prototyping and custom fabrication jobs

Production environments where flexibility is more critical than the highest hemming precision

Press Brake Hemming Dies vs 4 Way Press Brake Dies: Key Differences

While both die types are used on press brakes, there are significant differences in design, functionality, and application.

| Feature | Press Brake Hemming Die | 4 Way Press Brake Die |

| Primary Function | Specialized for edge folding (hemming) | Multi-functional: V-bend, U-bend, hemming, and more |

| Precision | Very high, ideal for critical folds | Moderate; versatile but may sacrifice some hemming precision |

| Flexibility | Single-purpose | Multi-purpose, suitable for various bends |

| Cost | Higher for specialized production | Economical for multiple bending tasks |

| Setup Time | Minimal once installed | Slightly longer if rotating or adjusting is needed |

| Best For |

Auto panels, appliances, aerospace parts |

Small to medium-batch production, prototyping, flexible manufacturing |

In essence, hemming dies are precision-focused, whereas 4-way dies prioritize flexibility and efficiency.

How Are These Two Press Brake Dies Related?

Interestingly, these two die types are not mutually exclusive. In fact, hemming dies are often a component of a 4-way die system. A 4-way press brake die may include a dedicated hemming module alongside V-bending and U-bending tools, allowing manufacturers to combine precision hemming with multi-functionality in one die set.

This relationship highlights a practical strategy in modern fabrication:

For high-volume, precision-critical hemming: Use dedicated press brake hemming dies.

For flexible production requiring multiple bend types: Use a 4-way press brake die that includes a hemming function.

Choose Between Press Brake Hemming Dies and 4 Way Dies

Selecting the right die type depends on your production requirements, volume, and precision needs. Consider the following factors:

Production Volume High-volume automobile or appliance production: Hemming dies ensure consistent quality.

Small to medium-batch or varied production: 4-way dies reduce setup time and inventory of multiple dies.

Precision Requirements If edge finish and fold accuracy are critical, specialized hemming dies are preferred.

For general bending operations with occasional hemming, 4-way dies suffice.

Cost and Tooling Management Dedicated hemming dies can be more expensive upfront but offer long-term quality benefits.

4-way dies save on the number of dies required, cutting initial tooling investment.

Material Type Some high-strength steels or thick aluminum sheets may require custom hemming dies to prevent cracking.

For moderate materials, 4-way dies provide sufficient flexibility.

Why Choose Anhui Tooling?

At Anhui Tooling, we specialize in high-quality press brake dies, including both press brake hemming dies and 4 way press brake dies. Here’s why manufacturers worldwide trust us:

Precision Manufacturing: Our hemming dies guarantee accurate folds and smooth edges, reducing rework and material waste.

Flexible Solutions: Our 4-way dies cater to versatile production needs, allowing multiple bends in a single setup.

Durable Materials: Made from hardened tool steel, our dies withstand high-pressure bending while maintaining precision.

Custom Designs: We provide tailored die solutions for auto, appliance, aerospace manufacturing, and general sheet metal industries.

Global Support: Anhui Tooling serves clients worldwide, ensuring timely delivery and technical guidance for die selection and maintenance.

Whether you require specialized hemming dies for high-precision panels or multi-functional 4-way dies for flexible production, Anhui Tooling offers professional solutions to optimize your press brake operations.

Conclusion

Understanding the distinction between press brake hemming dies and 4 way press brake dies is critical for efficient and high-quality metal fabrication.

Hemming dies excel in precision edge folding, ideal for applications demanding tight tolerances and smooth finishes.

4-way dies provide versatility and efficiency, suitable for multi-bend operations in small to medium-batch production.

The two types are complementary: a 4-way die may include a hemming function, allowing manufacturers to benefit from both precision and flexibility.

By carefully evaluating your production volume, precision requirements, material type, and cost considerations, you can select the right tooling for your press brake and enhance overall efficiency.

At Anhui Tooling, we deliver both specialized press brake hemming dies and versatile 4 way press brake dies designed to meet modern fabrication demands. Our commitment to quality, durability, and customization ensures that your press brake operations are both efficient and precise.

For inquiries or to request a custom die solution, contact Anhui Tooling today and take your sheet metal bending capabilities to the next level.

FAQ

Q1: What is the difference between press brake hemming dies and 4 way press brake dies?

A: Press brake hemming dies are specialized for high-precision edge folding, ideal for automotive panels and appliances. 4 way press brake dies are multi-functional tools that can perform V-bending, U-bending, and hemming in one die, offering flexibility for various bending tasks.

Q2: Can I use a 4 way die for precise hemming?

A: Yes, many 4 way dies include a hemming module. However, for the highest precision and edge quality, dedicated press brake hemming dies are recommended.

Q3: Which die is better for small-batch production?

A: 4 way press brake dies are ideal for small to medium-batch production because they reduce setup time and allow multiple bend types with a single die set.

Q4: Are Anhui Tooling’s dies customizable?

A: Absolutely. Anhui Tooling provides custom press brake hemming dies and 4 way dies tailored to your specific sheet metal thickness, bend radius, and production requirements.

Q5: How do I maintain press brake dies for long-term use?

A: Regular cleaning, proper storage, and timely lubrication are essential. Anhui Tooling also provides technical guidance for die maintenance to ensure durability and consistent bending quality.