Here are the top 9 Trumpf press brake tooling suppliers in 2025:

- TRUMPF

- Wila

- LVD Group

- Rolleri

- Mate Precision Tooling

- Wilson Tool International

- Promecam

- Anhui Tooling(High quality but low cost)

- Eurostamp Tooling

Precision, innovation, and automation drive performance in the metal fabrication industry. You benefit from quick tool changes, real-time feedback, and flexible solutions that meet modern manufacturing demands.

Feature | Performance |

Automation & robotics | Higher efficiency, precision, and safety |

AI-driven software | Enhanced accuracy and minimal manual intervention |

Adaptability for materials/thicknesses | Quick adjustments and tool changes |

Predictive maintenance | Increased productivity and repeatable, high-quality bends |

Selection Criteria for Trumpf Press Brake Tooling Suppliers

Choosing the right press brake tooling supplier shapes your production results and business growth. You need to evaluate several factors before making a decision. Industry experts recommend focusing on product quality, technological innovation, customer service, and global presence. In 2025, automation and smart fabrication technologies play a major role in your selection process. You want trumpf press brake tooling suppliers who invest in advanced solutions and support your need for precision and efficiency.

Quality

You should always prioritize quality when selecting press brake tooling. High-quality tools deliver consistent performance and reduce downtime. Poor tooling can deform workpieces, damage machines, or even cause operator injuries. Leading press brake manufacturers implement strict inspection processes and comply with industry certifications. You benefit from high quality tools that offer long-term value and competitive pricing.

Factor | Description |

Competitive Pricing | Value matters more than cost; superior quality justifies higher initial investment. |

Long-term Value | Durable tools mean less maintenance and better overall performance. |

Inspection Processes | Reliable manufacturers use thorough inspection and testing for every tool. |

Certifications Compliance | Industry standards and certifications guarantee quality assurance. |

Technology

You gain a competitive edge by choosing suppliers who embrace innovation. Modern press brake tooling features advanced high-strength steels, titanium alloys, and composite materials. These materials improve durability and support complex bending operations. Smart tooling systems now include IoT sensors for real-time monitoring and predictive maintenance. Some manufacturers use additive manufacturing to create intricate tool shapes and prototypes quickly. Eco-friendly materials and energy-efficient designs also help you meet sustainability goals.

- Advanced high-strength steels and alloys boost tool life and performance.

- Ceramic and carbide coatings reduce wear and improve part quality.

- Smart materials and sensors optimize tool performance and maintenance.

- Additive manufacturing enables rapid prototyping and complex geometries.

Service

Reliable customer service ensures you get the most from your trumpf press brake tooling investment. Top press brake tooling manufacturers offer comprehensive technical support and fast response times. You want suppliers who provide training, troubleshooting, and after-sales assistance. Industry reputation and customer reviews help you identify trustworthy partners. Cost-effectiveness matters, but long-term support and return on investment make a real difference.

- Responsive technical support keeps your operations running smoothly.

- Training and troubleshooting resources help you maximize tool performance.

- Positive industry reputation and reviews signal dependable service.

Top Press Brake Tooling Suppliers

TRUMPF

You can rely on TRUMPF for industry-leading trumpf press brake tooling. The company stands out with its commitment to exceptional quality and innovation. TRUMPF’s annual sales for 2023/24 reached approximately $5.58 billion USD, reflecting its global influence and trust among manufacturers.

TRUMPF offers production capacities for the TruBend 1000 series, with press forces from 66 to 353 tons and bending edges from 6.6 to 13.1 feet.

The company emphasizes energy efficiency and advanced technology in its products, supporting sustainability goals.

TRUMPF’s warranty policy includes a 1-year warranty on every TruBend CNC Press Brake and 24/7 technical support. You also receive a 90-Day Guarantee, allowing you to return the TruBend 2100 if it does not meet your expectations, with return shipping covered.

A recent case study from an automotive manufacturer highlighted the machines’ precision and reliability, noting minimal downtime and increased manufacturing efficiency. TRUMPF addresses common challenges in press brake tooling by offering expert support and modifying tooling designs to handle complex bending operations.

Wila

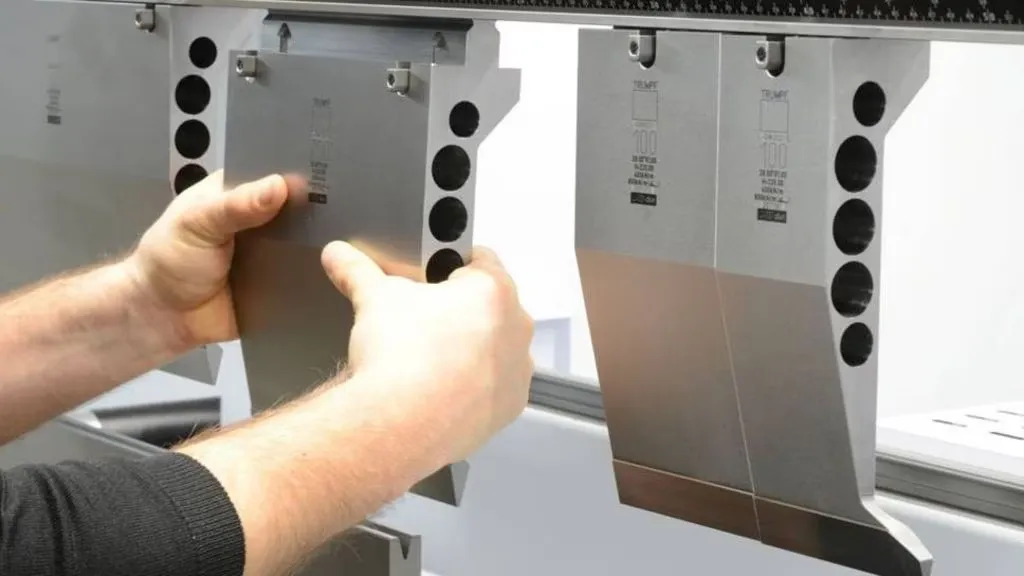

Wila’s trumpf press brake tooling stands out for its advanced retention mechanisms and operational efficiency. The Trumpf Style tooling from Wila provides higher clamping force, making it ideal for demanding manufacturing environments.

Wila’s design secures heavier punches, ensuring stability and precision even at high operational speeds. This approach delivers superior durability and speed compared to European Precision Style tooling. You can trust Wila for tooling that enhances both precision and productivity in your bending operations.

LVD Group

LVD Group offers a comprehensive range of press brake tooling and machines designed for flexibility and accuracy. You can choose from a variety of products tailored to different bending applications. LVD Group invests in smart fabrication technologies, supporting automation and real-time monitoring.

The company’s focus on digital integration helps you optimize your production processes and maintain consistent quality. LVD Group’s global presence ensures you receive reliable service and support wherever your operations are based.

Rolleri

Rolleri from Italy provides a wide selection of trumpf press brake tooling, including punches, dies, and accessories for various machines. You gain access to products engineered for durability and repeatability.

Rolleri’s trumpf tooling supports quick tool changes and adapts to different materials and thicknesses, improving your manufacturing efficiency. The company’s commitment to research and development ensures you benefit from the latest advancements in press brake tooling technology.

Mate Precision Tooling

Mate Precision Tooling offers a full array of punches, dies, and accessories in multiple sizes. You can select segmented, full-length, or half-length tooling options to suit your specific needs.

Mate has added over 500 new items across its tooling lines, including Amada height style profiles, to increase efficiency in press brake operations.

The company enjoys a strong reputation in the industry and provides an industry-leading warranty for European Precision Style and Wila Trumpf Style press brake tooling.

Mate’s products are manufactured from the finest tool steels with induction hardened wear surfaces, ensuring long-lasting durability.

With a 52-year history, Mate delivers tooling designed to enhance productivity and meet the demands of modern manufacturers.

Wilson Tool International

Wilson Tool International supports automation and smart fabrication with its advanced press brake tooling solutions.

Feature | Description |

Precision-ground punch and die | Designed for high-volume fabrication and robotic automation |

Tight-tolerance bending | Ensures accuracy in bending applications |

Advanced surface coatings | Enhances durability and compatibility with automation systems |

Thick tang design | Provides strength and safety in operations |

Compatibility with Wila-style clamping | Facilitates integration with existing systems |

You can rely on Wilson Tool International for tooling that integrates seamlessly with automated systems and delivers consistent results in high-volume production.

Promecam

Promecam has built a reputation for reliable customer support and after-sales service in the press brake tooling industry.

Established suppliers like Promecam offer high-quality products and dependable service.

Positive customer reviews highlight Promecam’s commitment to satisfaction.

The company provides regular maintenance, repairs, and upgrades, including tool sharpening and reconditioning, to keep your tooling in optimal condition.

You benefit from Promecam’s experience and dedication to supporting your bending operations over the long term.

Anhui Tooling

Anhui Tooling supplies a broad range of trumpf press brake tooling for manufacturers worldwide. You can find products that balance cost-effectiveness with durability.

Anhui Tooling focuses on meeting the needs of both small workshops and large-scale production facilities. The company invests in modern manufacturing processes to deliver tooling that supports consistent bending accuracy and reduces downtime.

Eurostamp Tooling

Eurostamp Tooling specializes in high-quality press brake tooling for Trumpf machines. You can choose from a diverse product portfolio that includes custom solutions for unique bending requirements.

Eurostamp Tooling emphasizes precision and reliability, helping you achieve repeatable results in your fabrication processes. The company’s focus on customer collaboration ensures you receive products tailored to your specific applications.

Trumpf Press Brake Tooling Profiles

You encounter a diverse range of press brake tooling suppliers, each offering machines and tooling designed for high-precision bending. TRUMPF leads with technologically advanced press brakes, while Wila, and LVD Group deliver reliable press brakes and customizable solutions. Rolleri and Mate Precision Tooling focus on durable and versatile press brakes, supporting high-quality results for various bending applications. Wilson Tool International, Promecam, Anhui Tooling, and Eurostamp Tooling provide products that meet the needs of both small workshops and large-scale manufacturers. You benefit from suppliers who prioritize bending accuracy and precision in every product.

Advantages

You gain several advantages by choosing top press brake tooling suppliers. These companies invest in advanced automation systems and bending technology, ensuring machines deliver consistent performance. You achieve high-precision bending with tooling that supports complex shapes and materials. Suppliers offer customized solutions and customizable solutions, allowing you to optimize your production for unique requirements. You experience reduced downtime and improved bending accuracy, thanks to robust inspection processes and innovative designs. High-performance machines and tooling help you maintain productivity and meet demanding fabrication standards.

Tip: Select suppliers who offer technical support and training. You maximize the value of your tooling investment and ensure high-quality results in every bending operation.

Products

You find a wide selection of press brake tooling and machines across these suppliers. TRUMPF’s TruBend 5000 Series and TruBend 7000 Series stand out for speed, comfort, and energy savings. LVD Group offer products with advanced automation and eco-friendly features. Wila and Mate Precision Tooling provide punches, dies, and accessories engineered for durability and bending accuracy. Rolleri, Promecam, Anhui Tooling, and Eurostamp Tooling deliver tooling for specialized bending technology and high-precision press brakes.

Here is a quick reference for typical tooling profiles:

Tooling Type | Description |

Punch | Upper press brake tooling, typically v-shaped to match the die. |

Standard Punch | Strong and stocky, ideal for thicker materials and higher loads. |

Acute Punch | Features an angle less than 90°, available in various degrees. |

Narrow Punch | Long, straight punches, also known as sword punches. |

Gooseneck Punch | Deep U profiles for large return flanges during bending. |

Die | Bottom press brake tool with one or more v-shaped grooves. |

Adjustable Die | V opening can be changed via a screw mechanism. |

Curling Tool | Creates a circular roll at the end of the sheet. |

Radius Tool | Designed for forming larger radii in the workpiece. |

Ribbing Tool | Adds round or v-shaped grooves to the sheet metal in a single stroke. |

You also see popular models in the Trumpf press brake tooling lineup for 2025:

Model Name | Features |

TruBend 5000 Series | Fast, precise |

TruBend 7000 Series | Focus on comfort, energy savings |

You select products based on your need for precision, bending accuracy, and high-quality results. Leading suppliers offer tooling and machines that support advanced bending technology and meet the demands of modern fabrication.

Press Brake Tooling Brands Comparison

You need a clear overview when comparing press brake tooling suppliers. The table below highlights the main strengths and weaknesses of each supplier. This helps you match your needs with the right partner for your machines and products.

Supplier | Strengths | Weaknesses |

TRUMPF | Advanced technology, reliable tooling, global support | Higher initial cost |

Wila | Strong retention, fast tool changes | Premium pricing |

LVD Group | Digital integration, flexible tooling | Smaller product range |

Rolleri | Durable products, quick adaptation | Less global presence |

Mate Precision Tooling | Wide tooling selection, long tool life | May require custom orders |

Wilson Tool International | Automation-ready, robust tooling | Niche focus on automation |

Promecam | Excellent service, reliable products | Fewer advanced features |

Cost-effective, broad range | Lower brand recognition | |

Eurostamp Tooling | Custom solutions, high precision | Longer lead times |

Tips

You want to make the best choice for your press brake tooling. Industry experts recommend several practical steps:

- Research each supplier’s reputation and customer reviews. This helps you find reliable partners for your machines and tooling.

- Look for suppliers with proven experience and a strong track record in press brake tooling.

- Evaluate customer service, including pre-sale consultation and after-sales support. Good support keeps your machines and products running smoothly.

- Consider the total cost of ownership. Focus on long-term value and tool lifespan, not just the upfront price of tooling.

- Match the supplier’s strengths to your specific needs. Some suppliers excel in automation, while others offer more flexible tooling or custom products.

Tip: Always test sample tooling with your machines before making a large purchase. This ensures compatibility and helps you avoid costly mistakes.

You improve your production results by choosing suppliers who support your goals for quality, efficiency, and innovation in press brake tooling.

You gain the most value by matching supplier strengths to your business needs. Review the table below to align your requirements with the right partner for precision and efficiency:

Factor | Description |

Material Thickness and Type | Choose tooling for your material and thickness to ensure accurate results. |

Bending Angle and Force | Calculate the angle and force needed for each job. |

Tonnage Requirements | Match tooling to your press brake’s tonnage for safe, efficient operation. |

Tool Profile and Load Limits | Select profiles that handle your maximum load without deformation. |

Tooling Style and Configuration | Pick a style that fits your machine and tasks. |

Machine Compatibility | Confirm compatibility for proper installation. |

Safety and Durability | Invest in durable tooling for consistent performance. |

FAQ

What factors should you consider when choosing a Trumpf press brake tooling supplier?

You should focus on quality, technology, customer service, and global reach. Reliable suppliers offer advanced tooling, fast support, and proven performance. Always check customer reviews and industry reputation before making a decision.

How do you ensure compatibility between tooling and your Trumpf press brake?

Check the tooling specifications against your machine’s model and requirements. Confirm dimensions, clamping style, and tonnage limits. If unsure, request a compatibility chart or consult the supplier’s technical team.

How often should you maintain or replace press brake tooling?

Inspect your tooling regularly for wear, cracks, or deformation. Replace tools that show signs of damage or reduced accuracy. Routine maintenance extends tool life and ensures consistent bending results.

Can you use automation with all Trumpf press brake tooling?

Not all tooling supports automation. You need to select tooling designed for automated systems. Look for features like quick-change mechanisms and sensor integration to maximize efficiency with robotic setups.