PRODUCTION PROCESS

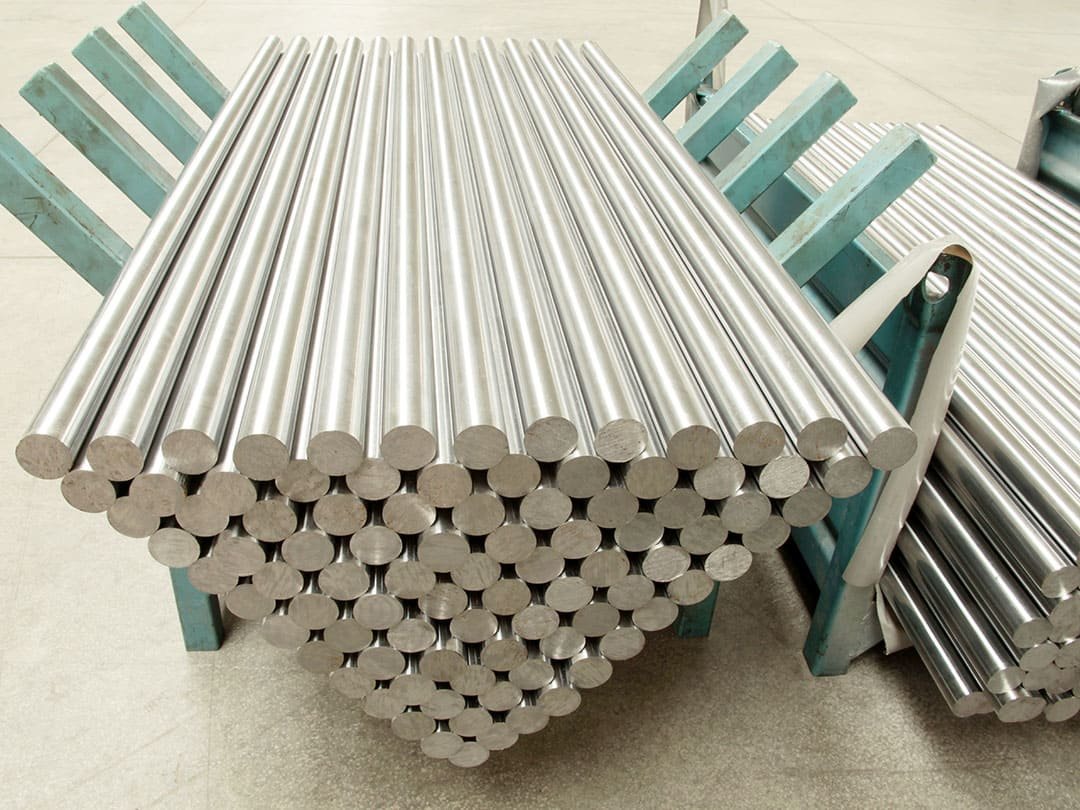

1. Selection Of Raw Materials

Choosing the right raw material is only the first step.For the manufacture of press brake tooling, 42CrMo material is the ideal choice, Its main properties are high strength, high hardenability, good toughness, small quenching deformation, high temperature creep strength and high durability. It’s able to withstand temperatures below 500 degrees, making it a versatile and reliable performance and superior processability, making it an ideal choice for even the most demanding applications. Furthermore, we can offer material option complying with customers’ demand.

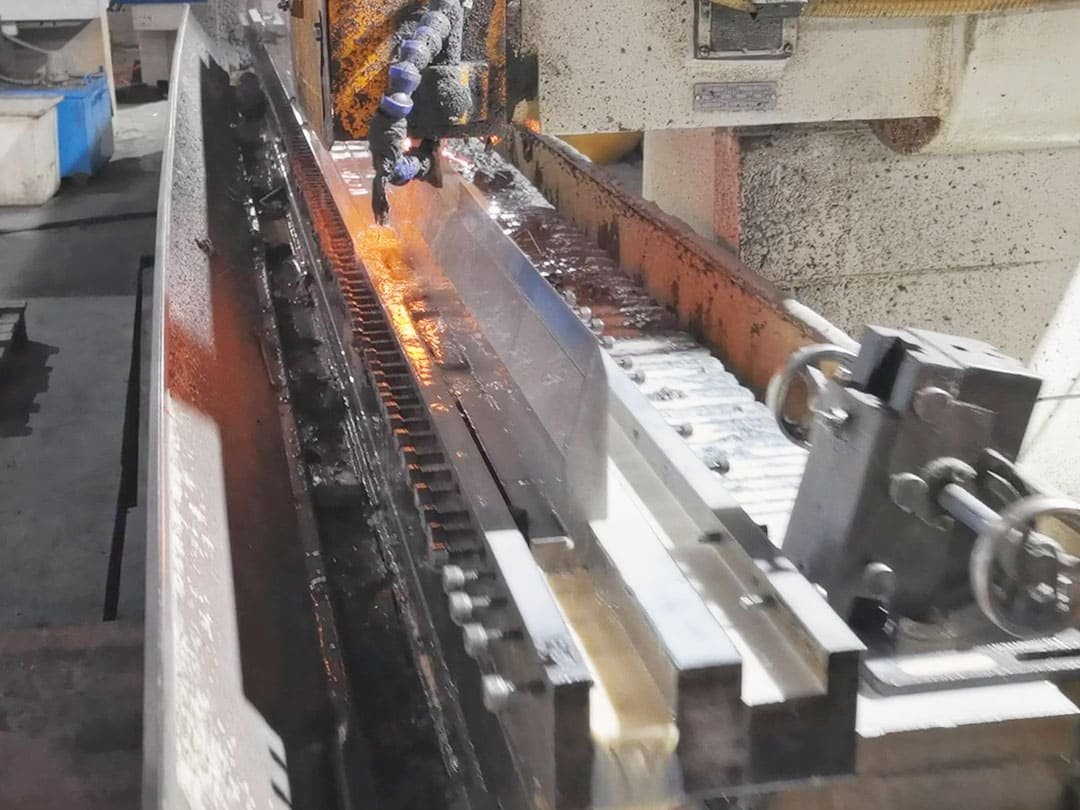

2. Material Blanking And Forging

High quality tools need to be forged. We cut the material of corresponding weight according to the drawing size, repeatedly forge it with an air hammer, and forge it to the overall dimensions of the mold and provide a machining allowance. Forging will not only allow us to obtain the corresponding size, but more importantly, it will increase the density and toughness of our press brake tooling, making them less likely to crack and break, making them stronger and more durable.

3. Rough Machining

Rough machining refers to the preliminary processing of the workpiece during the manufacturing process so that the required accuracy and surface quality can be more easily achieved in subsequent processing. Usually includes milling, turning, drilling, grinding and other processes. The purpose of rough machining is to remove burrs, oxides and other undesirable substances on the surface of the workpiece and form the preliminary shape and size.

4. Heat Treatment

Our press brake tooling undergo a rigorous whole hardening process,With a standard declared hardness of HRC48°±2 for the whole body, With a standard declared hardness of HRC54°-58° for the working area (mainly the shoulders of the die, and the tip of the punch), achieved through laser hardening of critical parts. Hardness can be adjusted according to application or customer needs.

5. Precision Machining

Thanks to our CNC milling machines and CNC grinding machines, its tolerance be controlled within ±0.03mm,This process provides the treated surface with an extremely high degree of finish. You can rest assured that your tools will perform to the highest standards and meet your exact specifications every time.

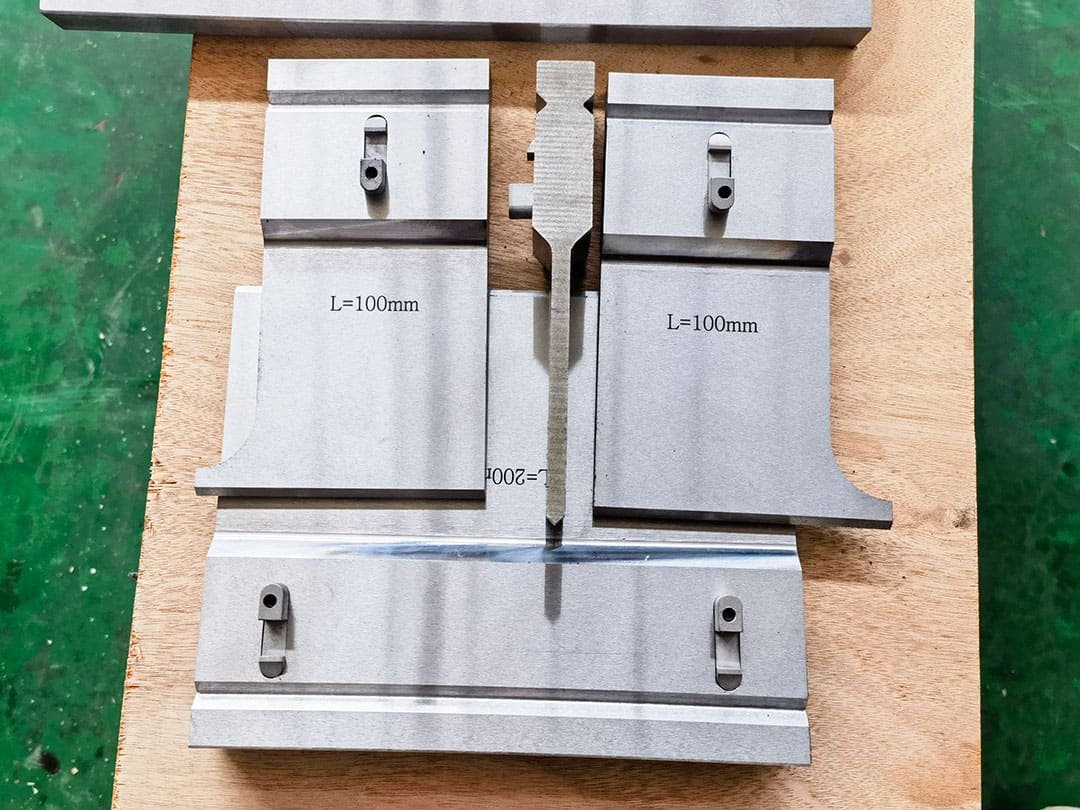

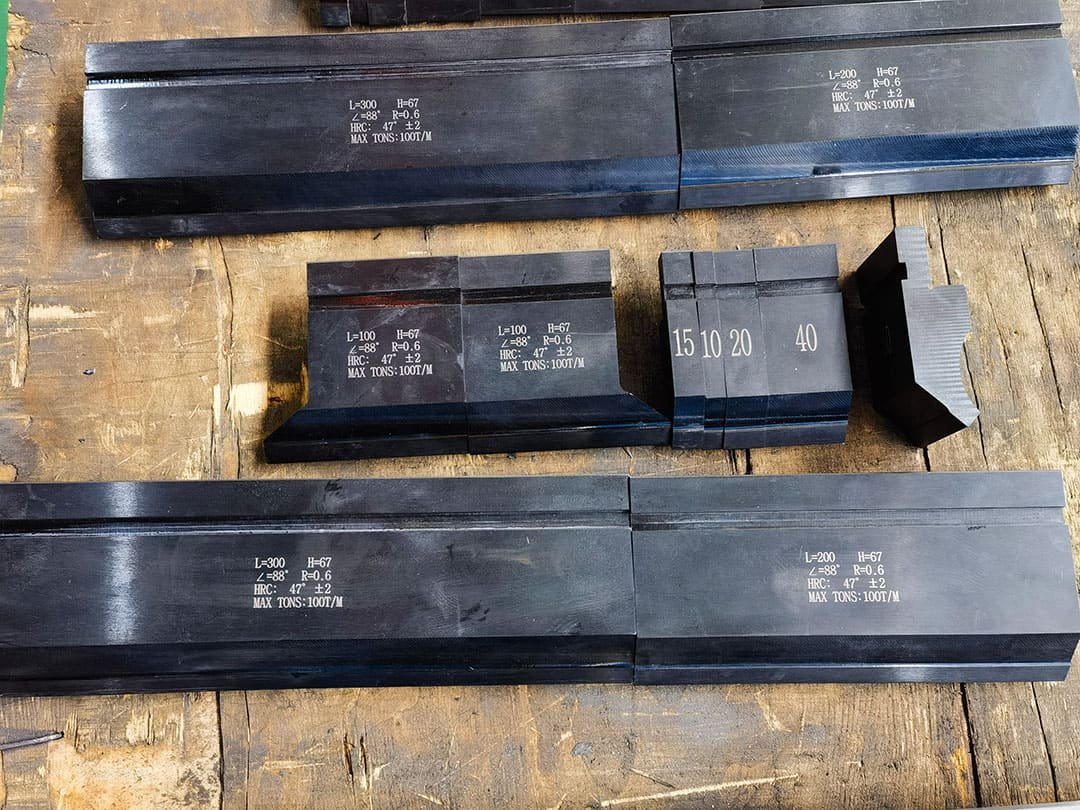

6. Tool Segmentation

ANHUI TOOLING offers the standard length of press brake tooling:835mm,805mm,800mm,550mm,515mm,510mm,500mm,415mm, 835mm, 835mm sectioned, 805mm sectioned, 550mm sectioned, 515mm sectioned.Can be segmented according to standard or segmented according to customer needs.

We also support customized sectionalized length of press brake tool, including special length and long length up to 2000mm or higher. We also provide long configurations of 6000-12000mm for heavy bending machine.

Trust us to design the tailored solutions to meet your bending requirements.

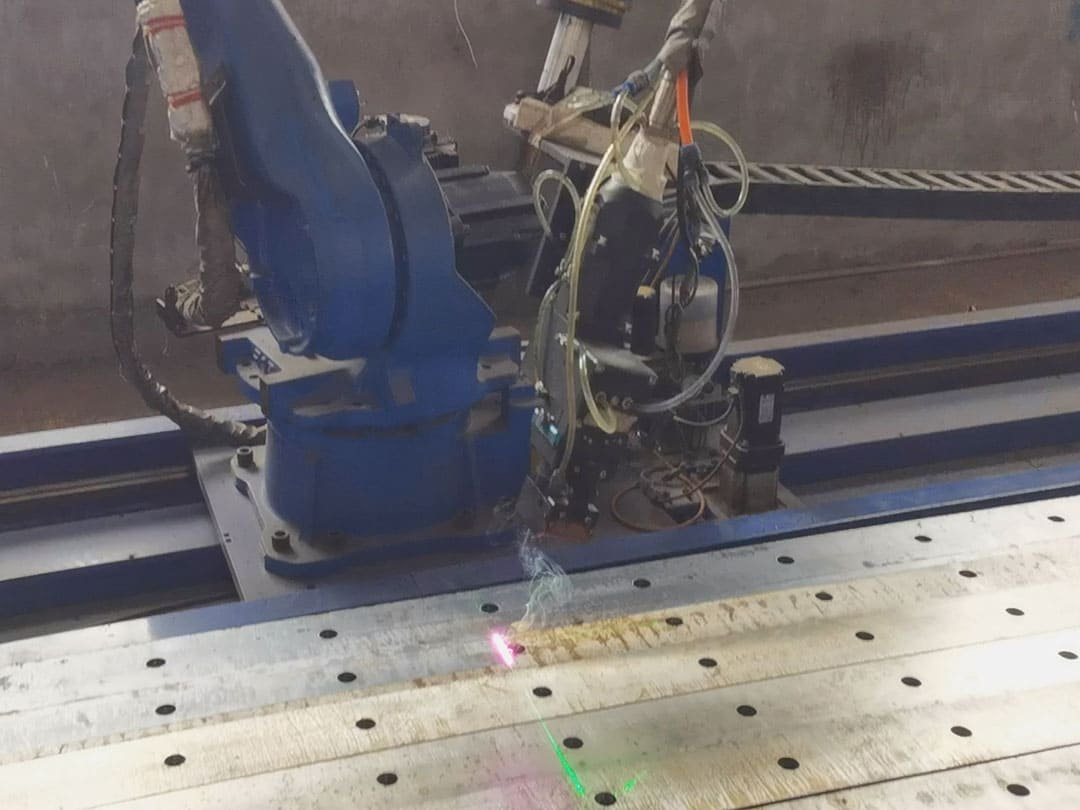

7. Laser Marking

Our press brake tooling come with laser marking that includes the tool’s code, angle, radius, die-opening, tonnage, and other important data, ensuring that you have all the necessary information at your fingertips. Laser marking is a non-contact and non-destructive process, making it a safer and more environmentally friendly option compared to traditional marking methods. Laser marking according to customer requirements, We have our own brand and also support OEM.

8. Quality Testing

Quality control is essential in our manufacturing process, ensuring that our products meet the highest standards of quality and reliability for our customers. We implement rigorous processes and procedures to ensure that every product meets our strict quality standards, Size inspection,Hardness testing,Die Bending Test,from raw material selection to finished product inspection. Only when the product quality inspection is qualified, will we arrange shipment.

9. Packing And Delivery

We use wooden boxes for packaging to better protect tools and export transportation.With our extensive inventory of standard tools in China, we’re able to provide lightning-fast delivery of standard pieces within just 2-3 days. For sectioned sets and cutting of tooling, we can typically have everything ready within a week. When you trust us with your tooling needs, you can count on us for speedy and efficient delivery every time.