Selecting the right press brake die can make a significant difference in your bending results. The choice between press brake U dies and V dies depends on your project’s specific needs, material properties, and desired bend shape.

Here’s a comprehensive guide to help you understand differences between U dies and V dies, applications, and how to make the best choice for your production process.

Press Brake Die Types Overview

Press brake dies are crucial for achieving precise bends in sheet metal. The die type affects the final shape, surface quality, and production efficiency. There are two main categories of dies:

- Upper Dies: Perform pressing, cutting, and shaping tasks, including shearing, arc, bending, and forming.

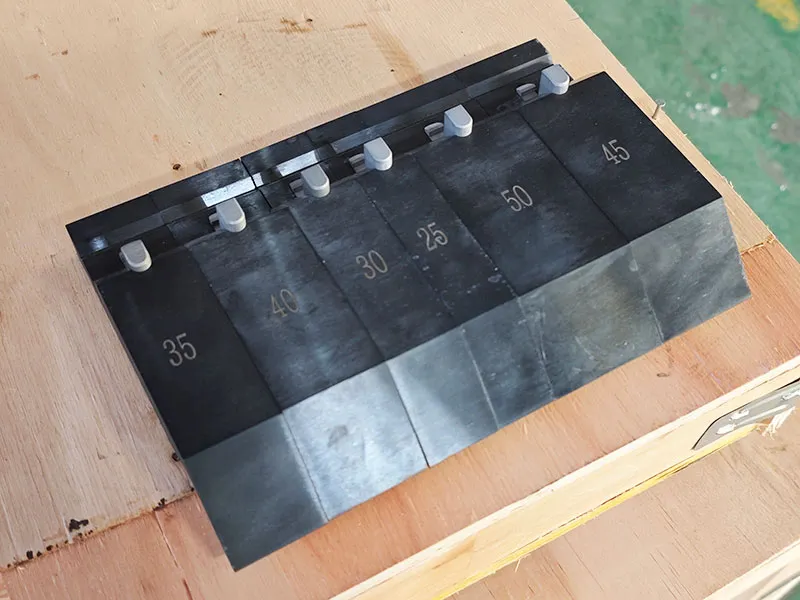

- Lower Dies: Provide support and positioning. Single-V dies offer basic support, double-V dies provide high precision, and multi-V dies accommodate more complex shapes.

Both U dies and V dies belong to these categories, but each serves a unique purpose depending on the bending requirements.

V-Die Structure and Features

V-dies feature a sharp V-shaped groove at the bottom, typically designed following the “8:1 principle,” meaning the opening is eight times the thickness of the sheet. V dies can be single-V, double-V, or multi-V, each designed for different bending needs. The V-die structure supports air bending, where the punch depth controls the bending angle.

Advantages:

- Ideal for producing bends with angles ranging from 30° to 180°.

- Flexible for various sheet thicknesses and materials.

- Quick adjustment between different groove sizes with multi-V dies.

- Suited for complex shapes, such as car body panels or structural components.

Applications: V dies are commonly used for a wide range of projects in industries like automotive, aerospace, and general sheet metal fabrication.

U-Die Structure and Features

U-dies have a U-shaped groove with rounded corners at the bottom. This design supports air bending for creating large inner radii or very acute angles. The rounded transitions help prevent the sheet from sticking and reduce surface scratches.

Advantages:

- Perfect for forming U-shaped channels or multi-flanged parts with smooth surfaces.

- Excellent for cylindrical or spherical shapes, such as automotive door frames and containers.

- Reduces the risk of material sticking, improving surface finish

Applications: U dies are primarily used in the automotive, appliance, and container manufacturing industries for parts that require smooth curves and precise geometry.

Comparative Analysis of U Dies vs. V Dies

| Feature | U Dies | V Dies |

| Bend Type | U-shaped, large inner radii, multi-flanged parts | Sharp angles, complex bends, and tight radii |

| Material Compatibility | Best for specific shapes like containers, flanges | Versatile, can handle different thicknesses and materials |

| Precision | High precision, great surface finish | Flexible but may require more adjustments for accuracy |

| Speed & Flexibility | Slower setup for specific parts | Quick adjustments between different bend shapes and materials |

| Ideal For | U-channels, frames, containers | Complex shapes, tight radii, varied thicknesses |

Application

U Dies:

Ideal for parts with consistent geometry, such as U-shaped channels, flanged parts, and cylindrical shapes. These are commonly used in the automotive, appliance, and container industries, where precision is crucial, and the parts require smooth corners and edges.

V Dies:

Provide flexibility for a wide range of projects, especially where material thickness varies or frequent size changes are needed. V dies are widely used for their versatility in handling different sheet thicknesses and achieving a variety of bend angles.

Bending Process Characteristics

The bending process differs depending on the die type:

U Dies:

The U-shaped groove supports the workpiece on both sides, ensuring parallelism and reducing the risk of surface scratches. This design allows for high forming accuracy, particularly for thicker or harder materials, and minimizes springback.

V Dies:

The sharp V-shaped groove allows for air bending, which is ideal for creating tight bends at angles ranging from 30° to 180°. V dies are suited for complex designs but may require more adjustments in setup, especially when switching between different material thicknesses.

Advantages and Limitations

V Dies:

- Advantages: Versatile, capable of creating tight bends and intricate designs. Cost-effective for projects with frequent size changes.

- Limitations: May not achieve the same surface quality as U dies for specific parts, and setup for complex bends can be more time-consuming.

U Dies:

- Advantages: Provides high precision and surface quality for forming U-shaped or multi-flanged parts. Less likely to produce scratches or defects.

- Limitations: Not as flexible as V dies for handling a variety of materials and thicknesses. Not ideal for complex or tight radii bends.

Press Brake Tooling Selection Guide

When choosing between U dies and V dies, consider the following factors to ensure optimal results:

Material Thickness and Hardness:

For thicker materials, U dies provide better support and minimize the risk of side bending.

V dies are better suited for thin sheets, offering flexibility and lower pressure requirements.

Surface Finish:

If surface quality is critical, U dies with rounded corners reduce the likelihood of scratches and other defects.

For high-precision, appearance-sensitive parts, ensure your dies have polished surfaces and are well-maintained.

Machine Compatibility:

Ensure your press brake machine can accommodate the selected die. Verify tonnage requirements and the machine’s ability to handle the desired die size and bend angle.

Common Selection Mistakes and How to Avoid Them

- Using an incorrect die opening for material thickness: This can lead to wear and poor bend quality. Always check the material’s compatibility with the die.

- Failing to match die geometry to the desired bend shape: This results in inaccurate bends. Make sure the die is appropriate for the angle and shape needed.

- Overlooking equipment compatibility: Mismatched dies and machines can cause damage. Always consult your CNC press brake’s specifications.

Enhancing Value with Precise Die Selection

Selecting the right die enhances production efficiency, reduces scrap rates, and ensures better product quality. The proper match between the die, material, and equipment leads to improved results. If unsure, consulting with an experienced supplier can help you choose the right die for your project.

By considering all these factors and consulting experts, you can achieve precise bends, high-quality finishes, and efficient production in your press brake operations.

FAQs

-

What is the main difference between U dies and V dies?

U dies form U-shaped bends with smooth corners, while V dies create sharp angles and are more versatile across a range of bend shapes and materials.

-

Can I use the same die for different materials?

No, material type and thickness significantly affect die selection. Always verify compatibility before starting the bending process.

-

How do I prevent surface scratches during bending?

Choose dies with polished surfaces and rounded corners. Regular die maintenance, such as cleaning and inspection, helps prevent scratches and surface defects.