Press brake tooling plays a vital role in precision metal forming. Over time, the performance and accuracy of these tools can degrade due to wear and surface damage such as scratches or galling. Early identification of precision loss and implementing effective onsite repair and prevention strategies can help manufacturers maintain product quality, reduce downtime, and lower costs.

Today, Anhui Tooling, as an experienced expert of press brake tooling is bout to elaborate how to detect tooling wear in its early stages and how to prevent and treat surface scratches on press brake dies.

Common Signs of Press Brake Tooling Wear

Tooling wear doesn’t happen overnight. It occurs gradually as a result of mechanical stress, repeated bending cycles, and contact with hard or abrasive materials. Recognizing early signs of tooling wear can help operators take proactive action.

1. Loss of Bending Accuracy

A noticeable sign of tool degradation is reduced bending precision. If parts begin to show dimensional inconsistencies despite proper calibration, it’s likely that the punch or die has worn edges or has lost its original profile.

2. Visible Edge Rounding or Deformation

Regular inspection of the punch and die can reveal rounded corners, cracks, or slight indentations. These imperfections may seem minor but can significantly affect the angle and quality of the bend.

3. Uneven or Inconsistent Material Flow

Worn tooling may cause materials to shift or slip during the forming process, resulting in inconsistent bends or surface warping.

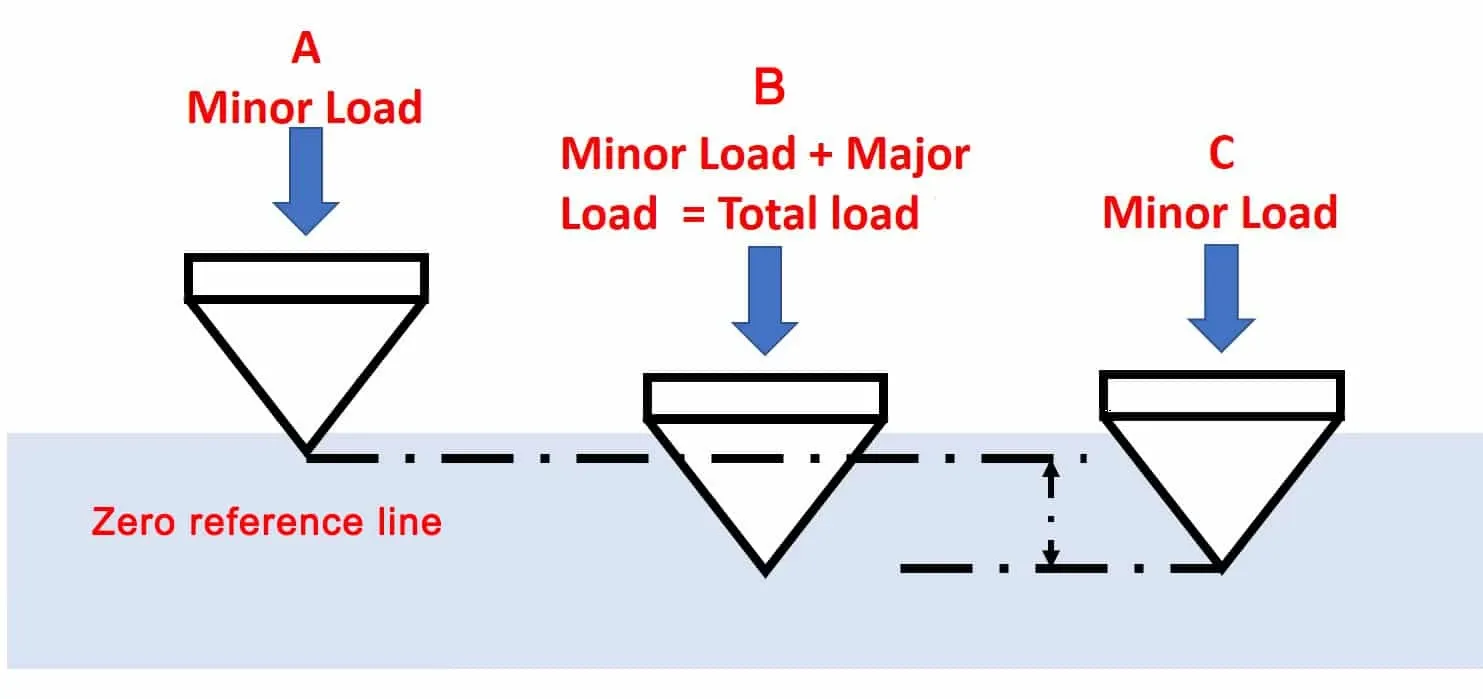

4. Increase in Required Tonnage

When tooling becomes dull or misaligned, operators may notice a need for higher force to achieve the same bend. This not only stresses the machine but accelerates tool damage.

Techniques for Early Detection of Tooling Wear

Being proactive is key. Here are several methods to identify wear before it affects production quality.

1. Regular Visual and Tactile Inspection

Establish a schedule for daily or weekly inspections using visual aids and magnifiers. Running a fingertip along the tool’s working edge can also help detect burrs, chips, or rounded surfaces.

2. Use of Precision Measuring Tools

Tools like calipers, micrometers, and optical comparators can help detect deviations in punch or die dimensions. Compare against original specifications.

3. Digital Profiling Tools

Advanced fabrication environments may use 3D scanning or laser measurement tools to generate digital models of tooling and detect profile deviations over time.

4. Monitoring Product Quality

Implement quality control checks at regular intervals to monitor part accuracy. Changes in bend angles, spring-back issues, or surface finish can indicate wear.

Onsite Repair and Maintenance Tips

When early signs of wear are detected, immediate corrective action can prevent further damage.

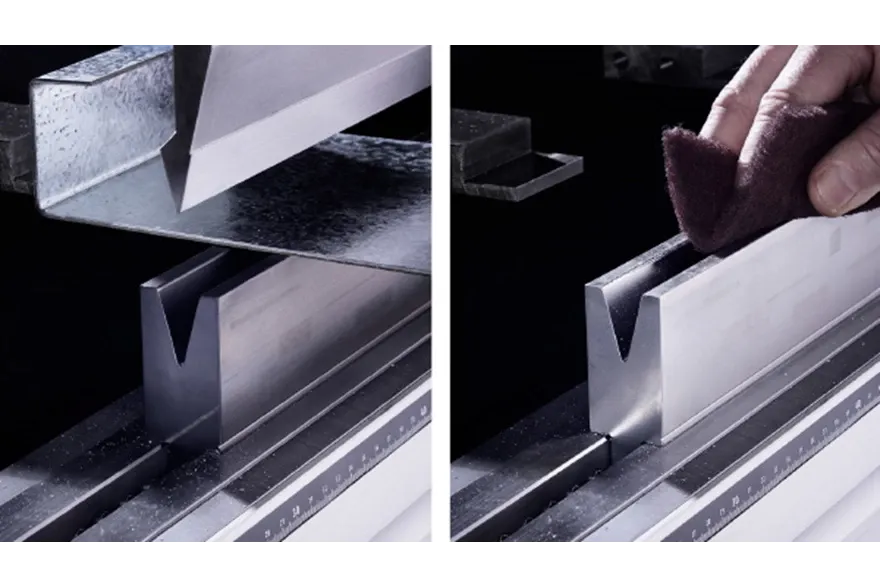

1. Surface Regrinding

Regrinding is a cost-effective solution to restore worn punches and dies. Ensure that the regrinding process maintains the original tooling profile and surface hardness.

2. Polishing and Deburring

Minor surface imperfections such as burrs or micro-chipping can often be addressed with fine polishing tools or diamond files. Avoid excessive material removal.

3. Hard Chrome Plating

For tools that frequently encounter abrasive materials, hard chrome plating can improve surface hardness and wear resistance.

4. Tool Alignment Checks

Misalignment between upper and lower tooling can accelerate wear. Ensure that both punch and die are correctly centered and mounted.

Causes of Surface Scratches on Press Brake Tooling

Surface damage such as scratches, galling, or material pickup on press brake tooling can significantly impact part finish and tool life. Understanding the root causes is the first step in prevention.

1. Dirty or Contaminated Workpieces

Dust, metal particles, or cutting fluid residues on the sheet metal surface can become embedded in the tooling during bending, causing scratches or indentations.

2. Improper Tool Material for the Application

Using standard steel tools to form hard or abrasive metals such as stainless steel or titanium may lead to rapid wear or galling.

3. Insufficient Lubrication

Dry bending or poor lubrication between the material and die surface increases friction and leads to heat generation, which can cause scratching.

4. Overload or Improper Tonnage Settings

Excessive bending force can press foreign particles into the tool surface or cause localized tool deformation.

Preventive Measures Against Tooling Scratches

1. Clean Workpieces Thoroughly

Always clean sheet metal surfaces before bending. Use air blowers or wipes to remove dust and metal shavings.

2. Apply Protective Films

Plastic protective films can shield delicate surfaces such as aluminum or polished stainless steel during forming.

3. Use Appropriate Tool Coatings

Nitrided or chrome-coated tooling provides better resistance against galling and surface damage, especially when working with stainless steel or other sticky materials.

4. Lubrication and Anti-Stick Agents

Use suitable lubricants or anti-stick sprays to minimize direct friction between the tool and the material.

5. Implement a Tool Rotation Schedule

Rotating tooling positions during production can distribute wear evenly and extend tool life.

Conclusion

Press brake tooling is an essential part of precision metal forming, and maintaining its condition is critical for consistent product quality and operational efficiency. By recognizing early signs of wear and understanding the causes of surface scratches, manufacturers can implement effective inspection routines, apply preventive measures, and conduct onsite repairs to maximize tool life. Investing in proper maintenance and using the right materials and coatings not only protects your tooling but also ensures smoother production with fewer defects and less downtime. Welcome to contact Anhui Tooling for durable and long-lasting press brake tooling!