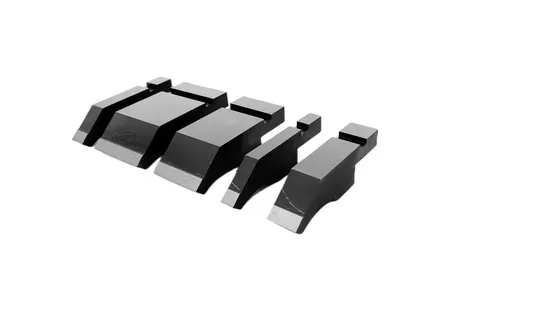

The longevity and performance of press brake tooling are pivotal to maintaining both production efficiency and product quality. As modern factories increasingly focus on reducing downtime, minimizing tooling costs, and ensuring consistent bending accuracy, press brake tooling with surface coating technologies have emerged as a critical factor in achieving these goals.

Whether you’re dealing with stainless steel, aluminum, or high-strength alloys, the right surface treatment—such as TiN coating or nitriding—can significantly enhance the wear resistance, reduce friction, and extend the life of your press brake punches and dies. Today we are bout to learn about the various coated press brake tooling options available, their benefits, and how they can revolutionize your bending operations.

Why Surface Coating Matters for Press Brake Toolings

Press brake punches and dies are subjected to tremendous mechanical stress during operation. Repetitive bending cycles, especially when dealing with abrasive or hard materials, can quickly wear down uncoated tooling. This leads to dimensional inaccuracies, tool replacement costs, and potential damage to finished workpieces.

Surface coating technologies aim to:

- Improve tool surface hardness

- Reduce wear and galling

- Enhance corrosion and oxidation resistance

- Decrease friction between the die and the workpiece

- Increase production consistency over long runs

By applying advanced coating techniques, tool manufacturers can drastically improve the performance of tooling, making it more suitable for demanding applications such as precision stainless steel fabrication or high-volume production lines.

Common Coating Technologies for Press Brake Tooling

Here are some of the most widely used coating methods that transform standard tools into premium-grade coated press brake tooling:

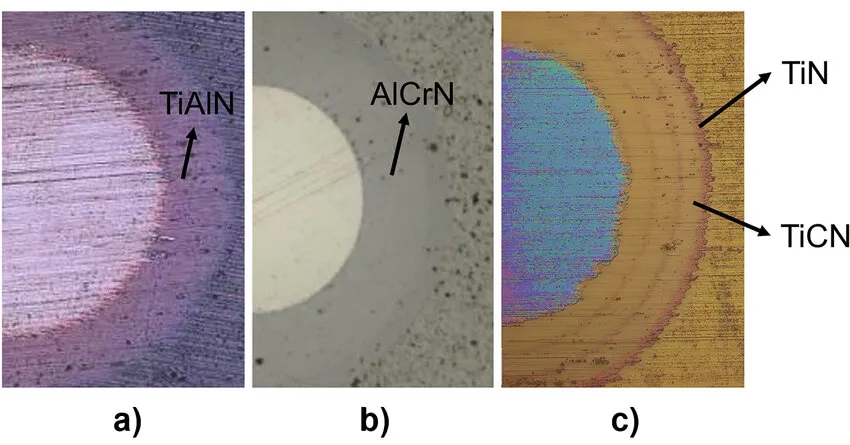

1. TiN Coating (Titanium Nitride)

TiN (Titanium Nitride) coating is one of the most recognized and widely used surface treatments in the metalworking industry. With a characteristic golden color, this ceramic material is deposited onto the tool surface through Physical Vapor Deposition (PVD) techniques.

Benefits:

- Hardness up to 2300 HV

- Excellent wear resistance

- Reduced friction coefficient (~0.4)

- Improved tool life by 3 to 5 times

- Aesthetic visibility for wear tracking

TiN coating is ideal for both punch and die applications, particularly when working with stainless steel or other sticky materials prone to galling. It’s a go-to option for high-end press brake operations.

TiN coating for press brake tools is especially effective in reducing tool maintenance and increasing the lifespan in demanding production environments.

2. Nitriding

Nitriding is a diffusion-based surface hardening process that introduces nitrogen into the surface layer of tool steel. This results in the formation of hard nitrides, significantly enhancing the surface hardness without altering the tool’s core properties.

Advantages:

- Surface hardness up to 1200 HV

- Excellent wear and fatigue resistance

- No dimensional distortion (low processing temperature)

- Enhanced corrosion resistance

Nitrided tools are often favored in heavy-duty applications and are particularly useful in applications involving mild steel and aluminum alloys. Compared to TiN, nitriding is more of a structural enhancement than a surface film.

3. TiCN and TiAlN Coatings

For more advanced or abrasive materials, enhanced coatings such as Titanium Carbonitride (TiCN) or Titanium Aluminum Nitride (TiAlN) offer additional benefits over standard TiN.

TiCN:

- Higher hardness (up to 3000 HV)

- Better wear and abrasion resistance

- Suitable for harder steels and alloys

TiAlN:

- Superior heat resistance

- Ideal for high-speed and high-temperature applications

- Excellent performance in dry bending (no lubrication)

These coatings are often used in automotive and aerospace sectors where both precision and durability are critical.

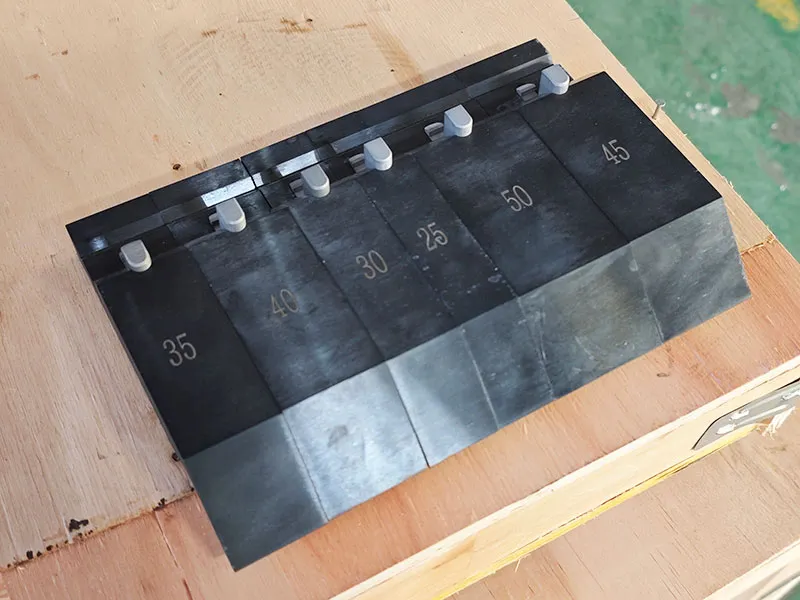

Choosing the Right Coating: Application Matters

While surface coating technologies provide significant benefits, selecting the right one depends on your specific application. Here are some guiding factors:

| Application Type | Recommended Coating | Reason |

| General Sheet Metal | Nitriding | Cost-effective, improved durability |

| Stainless Steel | TiN Coating | Prevents galling, extends tool life |

| High-Strength Steel | TiCN/TiAlN | Extra hardness and heat resistance |

| Aluminum | TiN or Nitriding | Minimizes sticking, easy release |

| High-Speed Bending | TiAlN | Withstands high temperatures |

For high-volume factories or specialized fabricators, investing in punch die coating technologies pays off quickly through reduced tooling downtime and consistent quality output.

Cost vs. Benefit: Is Coated Tooling Worth It?

While coated press brake tooling can come at a premium compared to uncoated versions, the return on investment is significant. Here’s why:

Longer Tool Life: Some coatings can triple or even quintuple tool life, saving on frequent replacements.

Less Downtime: Fewer tool changes mean more machine uptime.

Higher Quality Bends: Surface smoothness and hardness improve part consistency and reduce rework.

Less Lubrication: Lower friction reduces the need for external lubrication in some cases.

Enhanced Tool Storage: Coatings like TiN also protect against corrosion when tools are stored for long periods.

For high-end users or precision-driven operations, the upfront cost of coated tooling is justified by the performance gains.

Final Thoughts

In an industry where time, precision, and durability matter, surface treatment of press brake tooling is no longer an optional enhancement—it’s a strategic necessity. Whether you’re working with mild steel or exotic alloys, adopting TiN-coated punches, nitrided dies, or advanced TiAlN treatments can dramatically improve your forming process and reduce your overall operational costs.

As press brake tooling manufacturers continue to push the boundaries of material science, staying updated with the latest in punch die coating technologies will keep your fabrication line ahead of the curve.

If you’re looking to upgrade your tooling setup, now is the time to explore coated press brake tooling that matches your material demands and production goals.