Introduction

Traditional press brake tooling often struggles with parts that have narrow U-shapes, deep channels, or offset bends. A standard punch profile may interfere with the previously bent sections, making it impossible to complete additional forming operations. Gooseneck press brake tooling, with its curved profile, provides the necessary clearance to execute these bends effectively.

Standard press brake tooling often faces limitations when working with deep bends or complex part geometries, as it can interfere with previously formed sections. This is where gooseneck press brake tooling comes into play. With its specialized design, gooseneck tooling enables manufacturers to perform intricate bending operations without collisions.

What Is Gooseneck Press Brake Tooling?

Definition and Design of Gooseneck Tooling

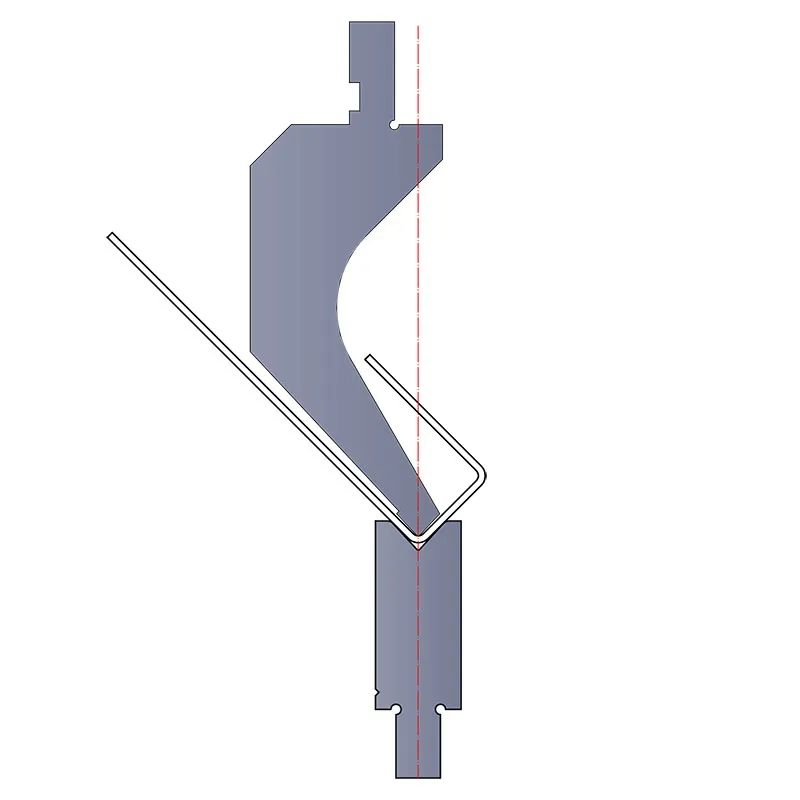

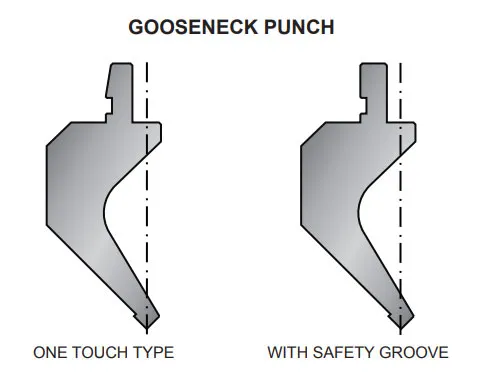

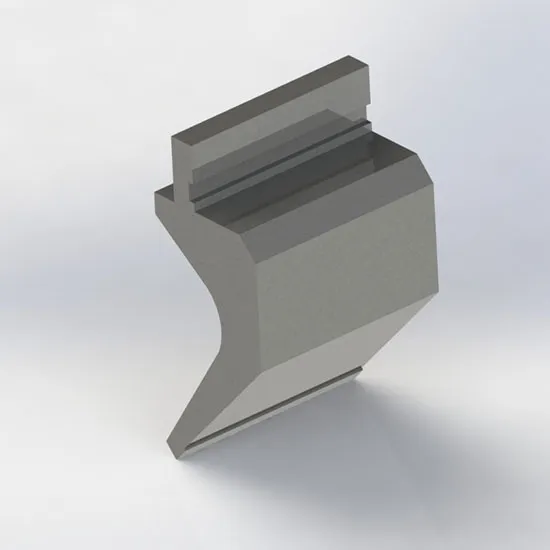

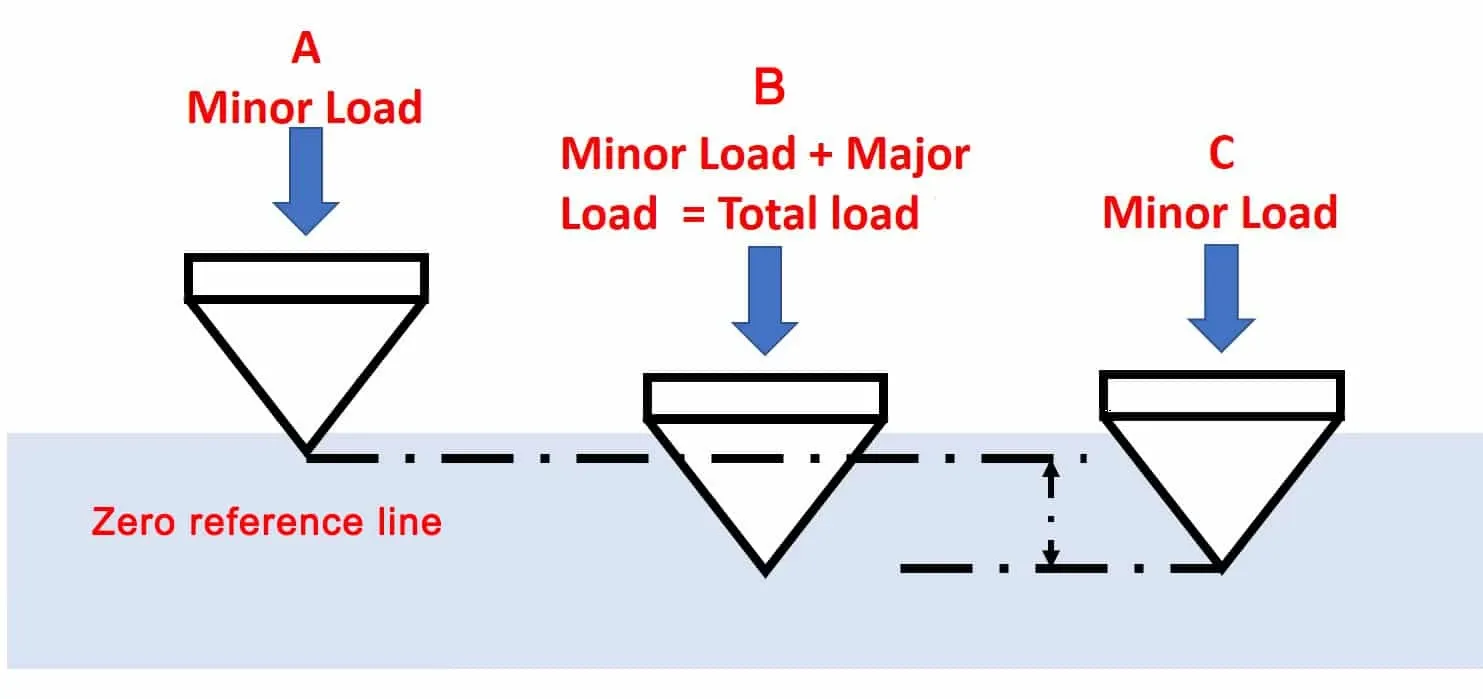

Gooseneck press brake tooling refers to a specialized type of press brake punch that features a curved or offset profile resembling the shape of a gooseneck. This design allows for deeper bending without the tool interfering with previously formed parts.

Unlike standard punches that have a straight or slightly angled profile, gooseneck tooling is engineered to accommodate complex bends, such as return flanges, Z-bends, and deep channels. The unique shape of the punch enables metal fabricators to form intricate shapes while minimizing the risk of collisions between the tool and the work piece.

How It Differs from Standard Press Brake Tools

- Offset Design– Unlike straight punches, gooseneck punches have a recessed profile, allowing clearance for previously bent sections.

- Increased Clearance– Ideal for forming deep channels or U-bends that would be impossible with standard tooling.

- Versatility– Gooseneck punches can be used in combination with different dies to create a wide range of shapes.

Gooseneck Dies in Bending

Advantages of Gooseneck Dies for Achieving Intricate Bends

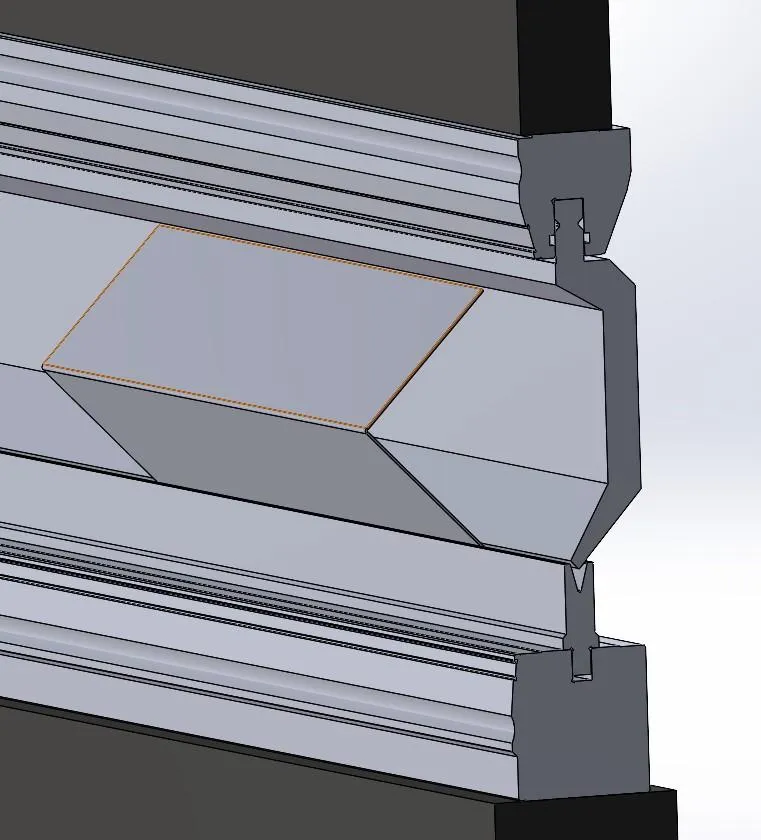

Gooseneck press brake dies are designed to complement gooseneck punches in executing complex bending operations. These dies help reduce interference issues, allowing for more intricate bends without compromising precision.

Key advantages include:

Avoiding Collisions– Their recessed profile ensures clearance for previously bent sections.

Supporting Multi-Stage Bending– Allows for sequential forming without excessive tool changes.

Enhanced Versatility– Suitable for various materials, including stainless steel, aluminum, and high-strength alloys.

Gooseneck Press Brake Punch in Tight Spaces

How Gooseneck Punches Allow for Bending Without Interfering with Pre-Formed Parts

The gooseneck press brake punch is the critical component that enables metal fabricators to form complex geometries. The punch’s offset shape provides the necessary clearance, preventing it from colliding with bent flanges or previously formed features.

This feature is particularly beneficial when working on:

Return Flanges– Bends that fold back toward the workpiece.

Z-Bends– Step-like bends requiring clearance for multiple angles.

Deep Channels– U-shaped bends used in structural components.

Selecting the Right Gooseneck Tooling for Your Press Brake

Factors to Consider When Choosing Gooseneck Tooling

Selecting the right gooseneck press brake tooling is essential to achieving the best results in metal bending. Consider the following factors:

Material Type and Thickness– Ensure the punch and die are designed for the material being processed. Some materials, like stainless steel, require more robust tooling.

Bend Radius Requirements– Different gooseneck punches have varying bend radii; choosing the right one ensures proper forming without excessive spring back.

Machine Compatibility– Verify that the gooseneck tooling is compatible with your press brake model and clamping system.

Durability and Wear Resistance– High-quality tool steel, such as hardened alloy steel or tungsten carbide-coated tooling, ensures longer lifespan and precision.

How to Ensure Compatibility with Different Press Brake Models

To ensure seamless integration, consider:

Tooling Length and Segmentation– Some operations require segmented tooling for flexibility.

Punch and Die Height Matching– Proper height matching avoids misalignment and uneven bending forces.

Press Brake Tonnage Capacity– Ensure the tooling can handle the required force without damage.

Conclusion

Gooseneck press brake tooling is an indispensable solution for complex metal bending applications. With its unique offset design, gooseneck punches and dies provide the necessary clearance to create deep bends, return flanges, and intricate shapes while maintaining precision.

By choosing the right gooseneck press brake dies and gooseneck press brake punches, manufacturers can enhance their fabrication capabilities, reduce material waste, and improve overall efficiency. Whether working in aerospace, automotive, or HVAC, investing in high-quality gooseneck tooling will ensure better results and longer-lasting tools.

If your operation requires precision metal forming with complex bends, gooseneck press brake tooling is the key to achieving superior results.