Rolla-v tooling can prevent bending material marking by combining rolling inserts with even force distribution. This design reduces friction and pressure points on your workpiece. Surface quality matters for sensitive bending, especially with soft or polished metals. Using this technology can help you achieve flawless results on delicate materials.

Material Marking in Sensitive Bending

What Causes Material Marking

Material marking often occurs during bending due to several factors. You may notice imperfections on your workpiece if the tooling is not properly maintained or if the environment is not clean. The most common causes include:

- Unpolished dies or damaged tooling can leave unwanted marks on the metal surface.

- Debris, dust, or metal shavings between the tool and sheet metal can create visible flaws.

- Mishandling, such as dropping or dragging the sheet, can result in scratches or dents.

Mechanical stresses also play a role. Stress concentrations may develop at certain points, leading to surface imperfections. Surface roughness can increase under mechanical loading, and thermal gradients during bending may cause residual stresses that promote defects.

Risks for Soft and Polished Metals

Soft and polished metals, such as aluminum and stainless steel, are especially vulnerable to marking. These materials require extra care to maintain their appearance and integrity.

|

Causes of Marking |

Solutions to Prevent Marking |

| Dirty, worn-out, or rough tooling surfaces | Apply protective films before bending |

| Inadequate lubrication | Polish or replace worn tooling regularly |

| Inappropriate material handling | Use softer dies, such as urethane or lined tools |

Markings on high-finish metals must remain clear and permanent, especially in industries like automotive and medical devices. Surface damage can lead to product replacement, quality control issues, and even recalls.

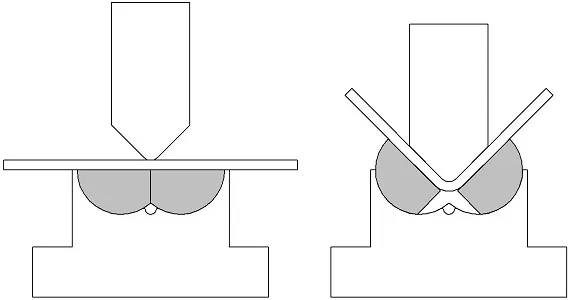

Traditional Press Brake Tooling Limitations

Traditional press brake tooling often struggles to prevent material marking. High localized pressure and friction during bending can cause dents and scratches, affecting both the look and quality of your parts.

Worn or misaligned punches and dies may increase friction, making visible marks more likely. Old V dies can create even more surface damage due to increased friction and poor alignment.

Rolla-v tooling offers a solution by reducing the risk of marking through its unique design and precision ground surfaces. This technology allows for cleaner bends, especially near holes and cut-outs, where traditional tooling may leave visible marks.

Rolla-V Tooling: Mark-Free Bending

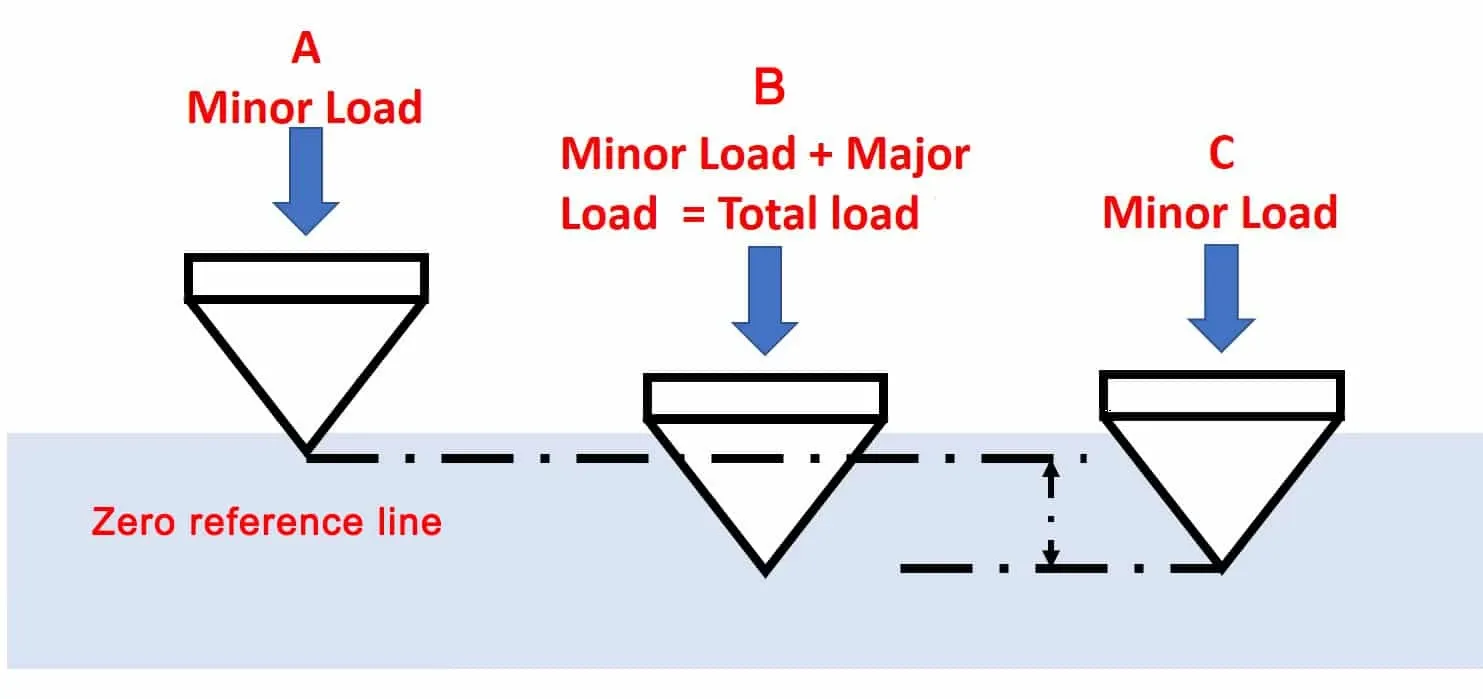

Rolling Inserts and Friction Reduction

Rolla-v tooling features a unique design that utilizes rolling inserts. These inserts rotate in sync with the sheet metal during the bending process. The rotation of the oscillating rotors significantly decreases friction resistance.

This mechanism can minimize deformation, especially in areas with holes and slots. The reduction in friction means that surface scratches and marks are less likely to occur. Many manufacturers favor it for its ability to maintain the integrity of sensitive materials. The rolling contact between the die and the workpiece may extend tooling life and improve overall part quality.

Even Force Distribution

The geometry of rolla-v tooling ensures that force is distributed evenly across the workpiece. The rolling inserts and V-shaped die work together to share pressure along the bend line. This even force distribution can prevent dents and surface damage, which are common with traditional press brake tooling. Consistent pressure may help achieve uniform bends, even on thin or soft metals. The design allows for precise control, reducing the risk of over-bending or localized stress.

Protection for Sensitive Materials

Sensitive materials, such as aluminum, stainless steel, and polished finishes, benefit greatly from rolla-v tooling. The precision-engineered geometry ensures clean and sharp bends with minimal marking. The rolling inserts provide gentle contact, which is essential for maintaining the surface quality of high-strength and high-finish metals. Metal fabricators in industries like automotive, aerospace, and electronics may require flawless surfaces for their components. Rolla-v tooling can meet these demands by minimizing the risk of scratches and dents. The rotating die is compatible with most press brakes, making it a versatile solution for a wide range of applications.

Tip: Rotating dies in rolla-v tooling may help reduce friction and extend the life of your press brake dies.

- Ideal for aluminum, stainless steel, and polished finishes

- Compatible with most press brakes

- May help achieve mark-free bends for visible parts

Rolla-v tooling stands out as a preferred choice for sensitive bending applications. The combination of rolling inserts and even force distribution can deliver superior results compared to traditional tooling.

Efficiency and Versatility of Rolla-V Tooling

Precision and Consistency

Rolla-v tooling can deliver precise and consistent bends, even on challenging materials. The rolling inserts support the sheet throughout the process, which may minimize distortion and ensure uniform results. Mark-free bending reduces the need for post-processing and rework, allowing for cleaner and more accurate parts.

Operators may rely on setup charts and documented procedures to maintain quality and reduce scrap rates.

Consistent results can help meet strict industry standards for visible or high-finish parts.

Versatility for Complex Bends

This Rolla-V tooling adapts to a wide range of metals and profiles. Customizable geometries allow for complex shapes that standard dies cannot achieve.

|

Feature |

Rolla-V Tooling |

Standard Dies |

| Customizable Geometries | Yes | No |

| Marks on Sheet Metal | Reduced marks, especially on sensitive materials | More marks due to friction |

| Suitable Materials | Stainless steel, aluminum, painted metal | Limited suitability |

Complex bends, small flanges, and profiles with holes or slots can be formed with minimal deformation. This versatility makes rolla-v tooling a preferred choice for industries requiring high-quality, mark-free parts.

Cost and Time Savings

Manufacturing environments may see significant cost and time savings with this tooling. Mark-free bending reduces the need for secondary finishing, which can lower labor costs and speed up production. The table shows the cost-saving advantages of Rolla-V tooling.

|

Cost Saving |

|

| Free Fabrication | Features like holes can be added without extra cost after initial tooling purchase. |

| Lower Part Cost | Efficient features lead to reduced part costs. |

| Lower Labor Costs | Roll forming can reduce labor costs to about 6% of total part cost. |

| Less Lead Time | Tooling offers lead times that are only 10% of those at job shops. |

| Optimized Parts | Participation in part design can optimize tooling and save costs. |

Reduced scrap rates and minimal post-processing further enhance efficiency, making rolla-v tooling a smart investment for high-quality manufacturing.

Rolla-v tooling’s rolling inserts and even force distribution can prevent material marking in sensitive bending. Manufacturers working with delicate, polished, or coated metals may achieve consistent, mark-free results.

| Tool Effectiveness | 3D printed plastic tools reduce costs and perform well on softer materials. |

| Material Performance | Good repeatability and minimal wear in softer steel DC04 materials. |

For reliable solutions in sensitive bending, consider Anhui Tooling’s rolla-v tooling solutions.

FAQ

How does rolla-v tooling help prevent surface marks?

Rolling inserts can reduce friction and distribute force evenly. This design may protect sensitive materials from scratches and dents during bending.

Which materials benefit most from rolla-v dies?

- Aluminum

- Stainless steel

- Polished finishes

These materials can maintain their surface quality with rolla-v tooling.

A mark-free process may reduce post-processing and scrap rates. Shops could see faster throughput and lower costs with rolla-v dies.