Press brake tooling plays a pivotal role in metal fabrication, directly influencing bend accuracy, efficiency, and tooling compatibility.

Among the most popular tooling systems worldwide, Trumpf style and American style press brake tooling dominate the industry. While both serve the same purpose—forming metal—they offer different structural designs, clamping methods, and operational advantages.

Understanding Press Brake Tooling Styles

Before diving into the comparison, it’s essential to understand what distinguishes tooling styles:

Tooling style refers to the physical design and interface of the punch and die used on a press brake machine.

Each style aligns with different machine brands and offers unique benefits in terms of ease of use, changeover speed, precision, and cost.

The trumpf vs. american debate is about speed, accuracy, and fit in the shop. Each tooling style has special features. Trumpf tooling has a 20mm wide tang with grooves. It also has an auto-clamping and self-seating design. American-style press brake tooling uses a 30-degree angle and simple clamping. Shops that want fast work may pick Trumpf. Shops that want more options or use old machines may pick American. The best choice depends on your machine, how exact you need to be, and your work goals.

|

|

Trumpf Style Tooling |

American Precision Style Tooling |

| Tooling Style | 20mm tang, auto-clamping | 30° angle, basic clamping |

| Compatibility | Newer CNC, high-speed presses | Older hydraulic, mechanical presses |

| Precision | High, consistent positioning | High, may lack long-term precision |

| Setup & Use | Quick changeover | Affordable, easy to use |

Differences: Trumpf vs. American Style Press Brake Tooling

Design & Construction

How press brake tooling is made affects how well it works. Trumpf-wila style tooling has a 20 mm wide tang with grooves on both sides. This helps it stay in place better. Lighter tools use a spring button for easy front loading. Heavier tools use a pin on the side to hold them tight. Trumpf tooling is built in parts, so you can change tools fast and line them up well. This makes it great for jobs that need high accuracy.

American-style press brake tooling uses a 0.500-inch wide tang. Its tang is simple and does not have two grooves. American style tooling is strong and can be used in many ways. It often comes in pieces you can put together for different setups. This style fits many press brake machines and lasts a long time. Shops can pick planed or precision-ground tangs, depending on how exact they need to be.

European-style press brake tooling, like Trumpf, focuses on self-seating and self-centering. These features help keep the tool straight and in the right spot. This is important for bending metal very accurately. American-style tooling lets workers adjust things by hand. This is good for shops that want more control over their tools.

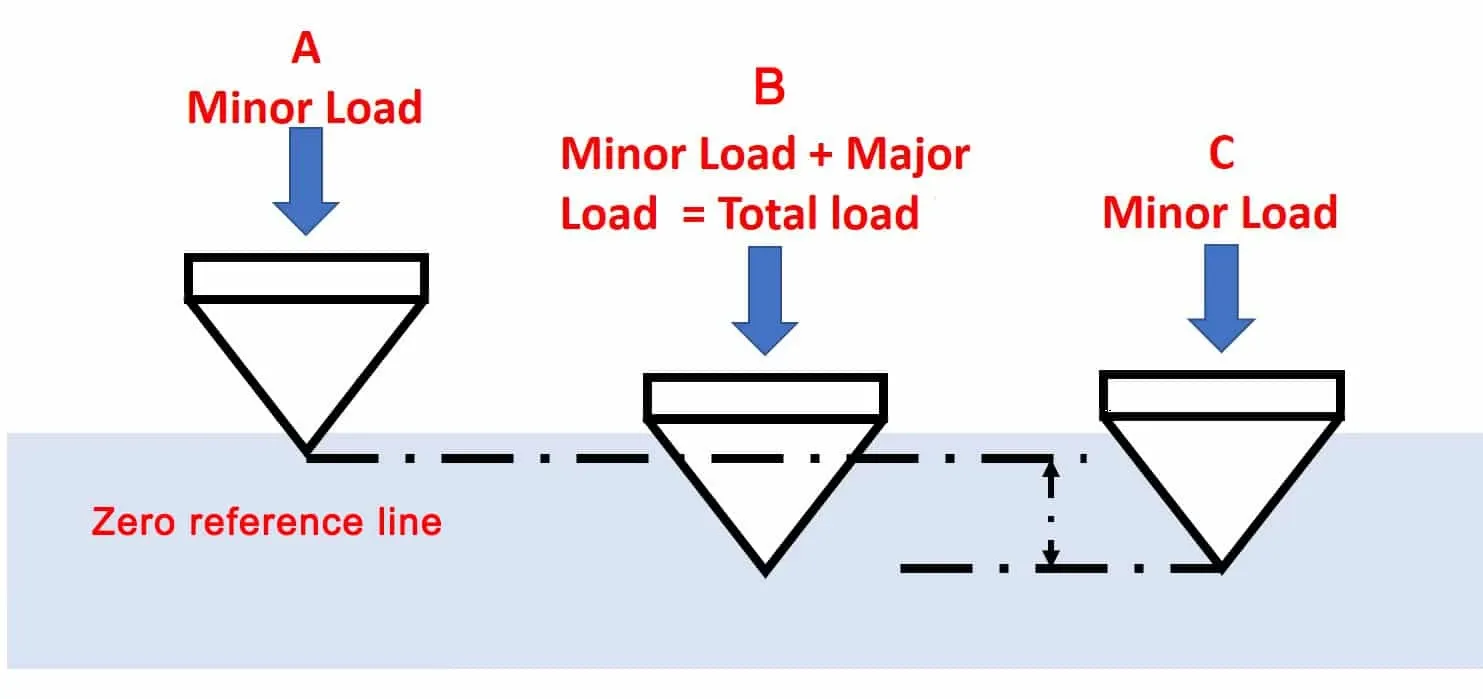

Force Application

How each tooling system pushes on the metal changes the bend and speed. American-style press brake tooling pushes straight down from the punch to the die. This makes sharp bends and saves energy. It works well with many types of metal and thicknesses.

Trumpf and American systems are different here. Trumpf and other European-style tooling push with force spread out along the tool. This keeps the bend angle even, even on big pieces. It also lowers the chance of the metal getting bent the wrong way. Trumpf’s strong build and force method help it bend metal the same way every time, even in tough jobs.

Clamping & Setup

How fast you can clamp and set up tools matters in a busy shop. Trumpf-wila style tooling has auto-clamping and self-seating. Quick-change buttons and side pins let workers swap tools fast. Hydraulic or automatic clamps make setup even quicker. This makes Trumpf tooling great for shops that do lots of work.

American-style press brake tooling uses easier clamping systems. Some new American systems, like WILA, have fast and safe clamps that help workers. The Maglock™ Magnetic Safety System uses strong magnets to hold punches during setup. But you still need to clamp them by hand when working. American style tooling can be changed quickly, but sometimes needs more hand alignment. This can slow things down in busy shops.

European-style press brake tooling, including Trumpf, often has smart features.

Compatibility

What machines the tooling fits is very important. Trumpf style tooling is made for Trumpf punch press machines. It works best with TRUMPF® TruPunch systems. This means it fits perfectly and works well, but it may not fit other brands.

American-style press brake tooling fits many kinds of machines. It works with Amada, Promecam, Bystronic, LVD, and some Trumpf and Wila systems. This makes it a good choice for shops with many types of machines. But the tang size and how the tool is held are different, so you cannot always swap tools between styles. This can limit what jobs you can do and how flexible your shop is.

Note: Knowing what tooling fits your machine keeps work safe and accurate. Picking the right tooling style helps you bend different shapes and materials without making big changes.

Applications

Each tooling system is best for certain jobs. Trumpf press brake tooling is great for high-precision and high-volume work. It can do many jobs, like 90° bends, U-channels, flattening, and tricky shapes with gooseneck punches. Trumpf tooling is made from strong materials and is heat-treated to last. It works well with both thin and thick metal, so it is good for simple and hard jobs in factories.

American-style press brake tooling is best when you need tools that can do many things. It is good for shops with many machines, easy to use, and saves money. American style tooling can do lots of different bends and is great for custom jobs and when you need to change tools often.

European-style press brake tooling, like Trumpf, is made for shops that want to work fast and get very accurate results. These systems are built for both easy and hard jobs and can meet many industry needs.

|

Feature |

American-Style Tooling |

Trumpf/European-Style Tooling |

|

Design & Construction |

Strong, comes in pieces, can be used many ways | Built in parts, quick to change, self-seating |

| Force Application | Pushes straight down | Force spreads out along the tool |

| Clamping & Setup | Manual or magnetic, some are fast | Auto-clamping, hydraulic, very quick |

| Compatibility | Fits many machines | Mostly for Trumpf machines |

| Applications |

Good for many jobs, flexible |

Best for high-precision, complex, big jobs |

| Efficiency | Good, but may take longer to set up | Excellent, made for speed and accuracy |

The main differences between Trumpf and American systems are how they are built, how they push on metal, how fast you can set them up, what machines they fit, and what jobs they can do. Shops should pick tooling that matches their work goals, machines, and how fast they want to work.

Precision and Accuracy

Trumpf Press Brake Tooling

Trumpf press brake tooling is known for being very exact. It works well in busy factories. Shops get good results by following clear steps:

- Pick the right tooling for the metal and bend. This helps the tool fit and keeps bends exact.

- Use lasers to line up punches and dies. This stops uneven wear and keeps things accurate.

- Check the tooling often. Workers look for cracks, rust, or if things are not lined up before and during use.

- Clean and oil the tooling after each shift. This stops rust and helps the tools last longer.

- Change old parts and check settings when needed. Doing this keeps the tooling working well and bends the same way every time.

Trumpf machines use CNC controls for exact moves and back gauges you can program. These features help stop mistakes and make work more even. Special bending tools let shops do many kinds of bends. CNC press brakes keep bend angles the same within ±0.5 degrees. This means parts stay the same size. Shops check the first part and keep checking as they work. This helps keep bends right and parts good. These steps make Trumpf tooling great for exact bends and lots of work.

Tip: Checking and caring for your tools often helps shops keep bends exact and parts good for a long time.

American-Style Press Brake Tooling

American-style press brake tooling is also very exact. It is even better when using precision-ground tools. Makers build these tools with very small error, often just ±0.02 mm (0.0008 inches). This is important for jobs like making airplane or medical parts, where every part must be just right.

|

Feature |

Specification |

| Working Surface Tolerance | ±0.02 mm (0.0008 inches) |

| Material | High tensile CrMo steel alloy |

| Hardness | CNC-Deephardened to 52° Rc min |

| Application | Precision American-style press brake tooling suitable for precision applications |

Precision-ground American-style tooling makes sure all tools in a set are the same. This helps shops bend metal the same way every time and get good results. Shops can keep bends close to the right size, but must watch for changes in metal thickness and other things that can change the bend. This tooling is a top pick for custom jobs and when you need both exact bends and tools that can do many things.

Pros and Cons

Trumpf Tooling

Trumpf tooling is special because of its smart design. Shops can set up tools fast with auto-clamping and self-seating. This tooling gives the same results every time and is very exact. It works well in busy places that need perfect bends. The strong build means it lasts a long time, even if used a lot.

But, Trumpf tooling costs more at first than American-style systems. The fancy design and quick punch setup add to the price. Many shops think the fast tool changes and use with robots make the cost worth it later. Trumpf tooling is best for big jobs where speed and accuracy matter most.

Note: Trumpf tooling works really well and is high quality. It is a good pick for shops that want to work fast and get exact bends.

Pros:

- Quick to set up and change tools

- Very exact and does the same thing each time

- Strong and made to last

- Works great in robot and big jobs

Cons:

- Costs more at the start

- Does not fit many non-Trumpf machines

American-Style Press Brake Tooling

American-style press brake tooling is great for shops that do custom work. The pieces can be mixed to make many punch and die shapes. This helps workers bend different metals and shapes fast. Shops that do lots of different jobs like how easy it is to switch setups.

American-style tooling usually costs less, so it is good for shops that need to save money. The simple design and fit with many machines make it even better. This tooling works well and is good quality, but may not stay as exact or work with robots like Trumpf.

|

Pros |

Cons |

| Costs less | May need more hand setup |

|

Easy to use for custom jobs |

Setup can take a bit longer |

| Fits many press brake machines | May not stay as exact over time |

| Works well for many kinds of jobs | Has fewer robot features |

Tip: American-style tooling is best for shops that want to save money and do many different jobs.

Choosing Tooling

Factors to Consider

Picking the right press brake tooling depends on a few big things. First, you need to make sure the tooling fits your machine. Shops have to check if their press brake works with the tooling they want. How much you make each day also matters. If you make a lot of parts, you may want tooling that changes fast and saves time. The kind of metal you use is important too. Some tooling works better with thick or hard metals. This helps you do tough jobs without problems.

The table below shows how making lots of parts and using different metals can change which tooling is best:

|

Factor |

American Precision Style Tooling |

Trumpf (Wila Trumpf Style) Tooling |

| Compatibility | Widely compatible with various North American press brakes | Designed for machines requiring high precision and quick changes |

| Precision | Good precision and versatility | Exceptional precision with quick tool changing capabilities |

| Ease of Use | Straightforward, robust, and versatile | Highly efficient for fast changes and high-precision tasks |

| Production Volume | Suitable for general use and potentially higher volumes where broad compatibility matters | Preferred for high production volumes needing fast tooling changeovers |

| Material Type Impact | Versatile for a range of materials but less efficient for quick changes | Supports high precision and quick changes, beneficial for diverse or challenging materials requiring higher tonnage |

Tip: Always pick tooling that matches how your shop works and the jobs you do most.

Application Scenarios

Every shop has its own needs. Small and medium shops often pick American-style press brake tooling. They like it because it is flexible and saves money. These shops do many kinds of bends and want tools that work well for lots of jobs. Big shops or shops that bend tricky shapes may choose Trumpf tooling. Trumpf tooling is good for fast changes and doing the same bend over and over.

One medium shop said they worked 10% faster and spent 5% less money after using CNC press brakes with American-style tooling. Their setup time went from 30 minutes to 15 minutes. They got their money back in just under four months. Using quick-change and automation features also cut labor costs by 25% in a year. These changes show that the right tooling can help shops work better and faster.

Cost vs. Performance

How much tooling costs is always important. Trumpf press brake tooling costs more at first. But many people say it is worth it because it works well for a long time. Car makers like Trumpf because it does not break down much and always makes good parts. This means they can make more parts and spend less fixing machines. Taking care of your tooling helps it last longer and keeps your machine working well.

American-style tooling is a good deal for small and medium shops. The table below shows how shops can save money and work better:

|

Features |

Example / Result |

| Productivity Increase |

10% boost over two years |

| Cost Reduction | 5% drop in production costs |

| Payback Period | 3.8 months after setup time reduction |

| Labor Savings | 25% reduction in labor costs within a year |

| Quality Improvements | Fewer defects and higher customer satisfaction |

| Material Usage Optimization | 15% less material waste |

Note: Shops should think about both the starting price and how well the tooling works over time. The right tooling can help you save money now and later.

Industry experts say the best tooling depends on what your shop needs. The table below shows the main differences:

|

Aspect |

Trumpf (Wila) Tooling |

American-Style Tooling |

| Tool Change Speed | Very fast | Slower |

| Tonnage Capacity | Up to ~160 tons/meter | Up to ~100 tons/meter |

| Application Suitability | Robotic cells, heavy-duty tasks | Universal use, cost-effective |

| Cost | Higher | Lower |

Shops that want fast work and use robots often pick Trumpf. Shops that want to save money and do many jobs pick American-style. Every shop should think about what it needs and talk to suppliers to find the best tooling.

FAQ

What makes Trumpf tooling faster to set up than American-style tooling?

Trumpf tooling has auto-clamping and self-seating. Workers do not need to line up tools by hand as much. This lets them change tools fast. Shops save time and get more work done.

Can American-style tooling work on modern CNC press brakes?

Yes, American-style tooling fits many new CNC press brakes. Many companies make adapters and clamps for these tools. This helps them work on modern machines.

Which tooling style offers better long-term durability?

Both Trumpf and American-style tooling use strong steel and heat treatment. Trumpf tooling often lasts longer in busy shops. This is because it is built strong and fits very well.

Is it possible to mix Trumpf and American-style tooling in one shop?

Shops can use both styles if they have the right clamps and adapters. Mixing tooling can take more time to set up. It can also make things less flexible. Planning ahead helps stop problems with fitting tools.