When it comes to metal press brake dies, it is essential to understand material hardness for achieving durability, precision, and long-term performance. One key measurement used in this context is HRC, which stands for Hardness Rockwell C — a scale that indicates a material’s resistance to deformation and wear.

What is HRC?

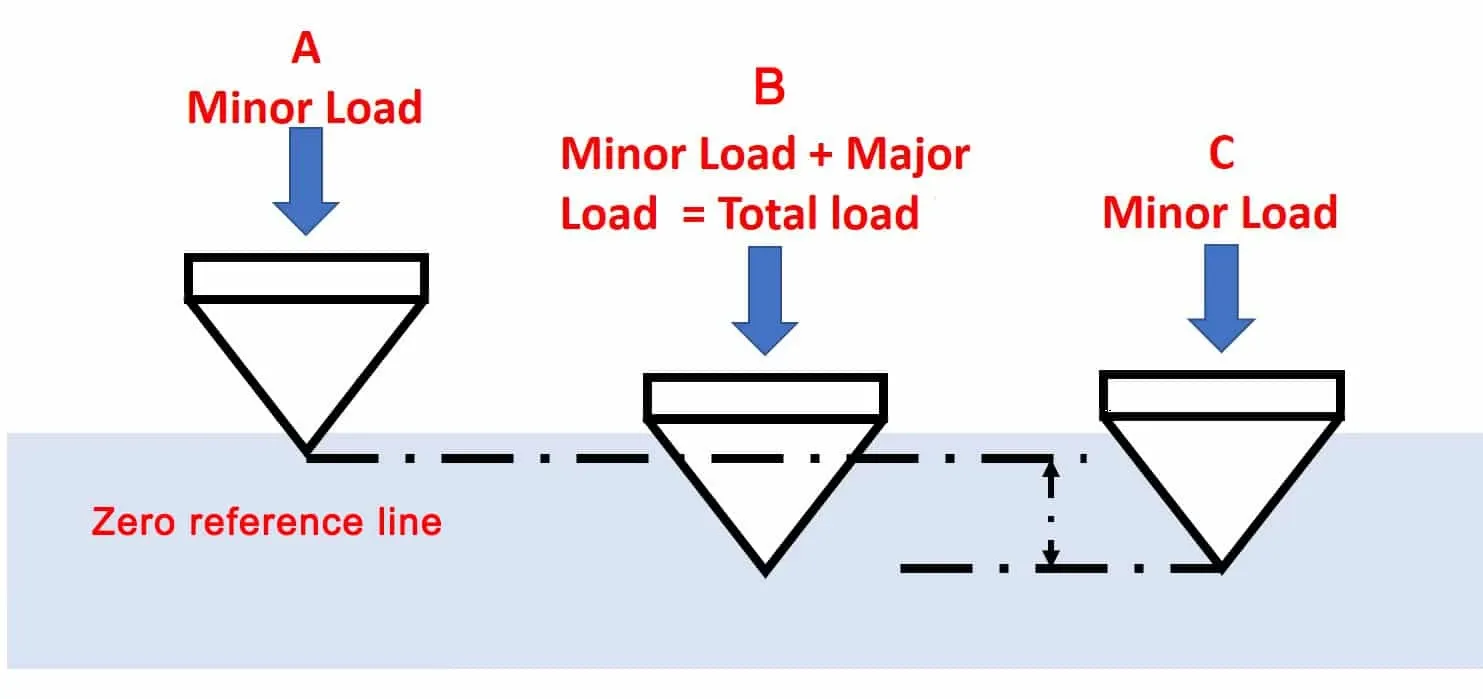

HRC (Hardness Rockwell C) is a unit on the Rockwell hardness scale, a standardized method for measuring how hard a material is, particularly metals. The Rockwell C scale is used for harder metals such as tool steels and measures hardness using a diamond cone indenter under a 150 kg load.

In simple terms, the higher the HRC value, the harder the metal. For example:

- Mild steels generally have an HRC between 20–30.

- Tool steels used for press brake dies usually range between HRC 48–60.

- Materials exceeding HRC 60 offer excellent wear resistance but may be more brittle.

In press brake tooling, HRC provides a clear indicator of how well a die can resist deformation and wear during repeated bending operations. Finding the right balance between hardness (for wear resistance) and toughness (to prevent cracking) is crucial.

Why HRC Matters in Press Brake Dies?

In the press brake bending, the HRC rating directly influences die performance, lifespan, and reliability. Here’s why it plays such a vital role:

1. Wear Resistance

A higher HRC value generally means better wear resistance. Since dies are repeatedly subjected to high pressure and friction, harder dies maintain their shape and precision longer.

2. Tool Life

Dies hardened to HRC 56–60 can withstand more bending cycles, especially when working with high-strength or abrasive materials. This leads to reduced downtime and lower replacement costs.

3. Bending Accuracy

A die with proper hardness resists deformation, ensuring consistent angles and precise bends. Softer dies, on the other hand, may deform over time, compromising bending accuracy.

4. Material Compatibility

Choosing the right hardness level depends on the material being bent. For stainless steel or high-tensile alloys, higher HRC values are essential to prevent premature wear.

5. Crack and Breakage Prevention

While higher hardness improves wear resistance, it can also make a die more brittle. That’s why controlled heat treatment and balanced hardness are key to ensuring both toughness and longevity.

How HRC Affects Tool Life and Bending Accuracy?

The HRC level of a die directly affects its longevity and bending precision:

Tool Life: A die with HRC 50–55 can endure tens of thousands of bending operations without significant wear, making it ideal for mass production or continuous bending tasks.

Bending Accuracy: Proper hardness allows the die to maintain its original geometry, ensuring repeatable results. Softer dies may lose shape over time, leading to inconsistent bends or poor part quality.

However, it’s important to remember that hardness should always be balanced with toughness. A die that’s too hard might be prone to chipping or cracking under impact or misalignment.

How to Choose the Right HRC Level for Press Brake Dies?

Selecting the appropriate HRC value depends on several key factors:

Material Being Bent:

For mild steel or aluminum → HRC 45–50 is sufficient.

For stainless steel or carbon steel → choose HRC 50 and above.

Production Volume:

Low-volume jobs can use softer dies.

High-volume operations benefit from harder dies to extend service life.

Die Shape and Size:

Complex or narrow dies should have slightly lower hardness to avoid cracking.

Standard dies can safely have higher HRC.

Heat Treatment Quality:

Always select dies with uniform heat treatment to ensure consistent hardness and eliminate weak points.

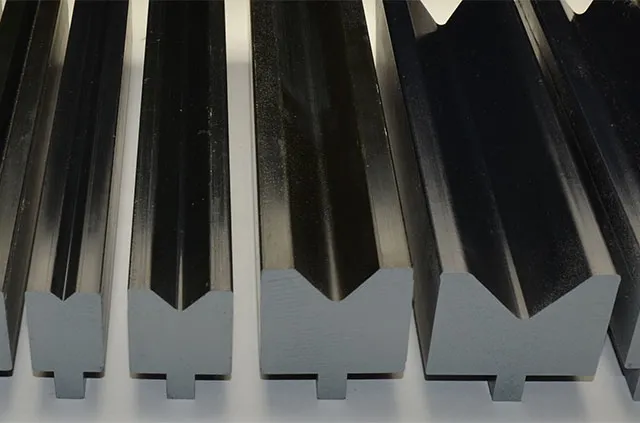

About Anhui Tooling

Anhui Tooling is a trusted manufacturer specializing in precision press brake dies designed for a wide variety of metal bending applications. With advanced heat treatment technology and strict quality control, Anhui Tooling produces dies within the HRC 45–50 hardness range, custom hardness is also available request, achieving the perfect balance between wear resistance and toughness.

Our products are engineered for accuracy, consistency, and long-term reliability, ensuring stable performance in both low- and high-volume production environments. Whether you’re bending mild steel, aluminum, or stainless steel, Anhui Tooling’s press brake dies deliver precise results and exceptional tool life.

Choose Anhui Tooling for dependable craftsmanship, consistent quality, and professional technical support — your reliable partner for high-performance press brake tooling solutions.