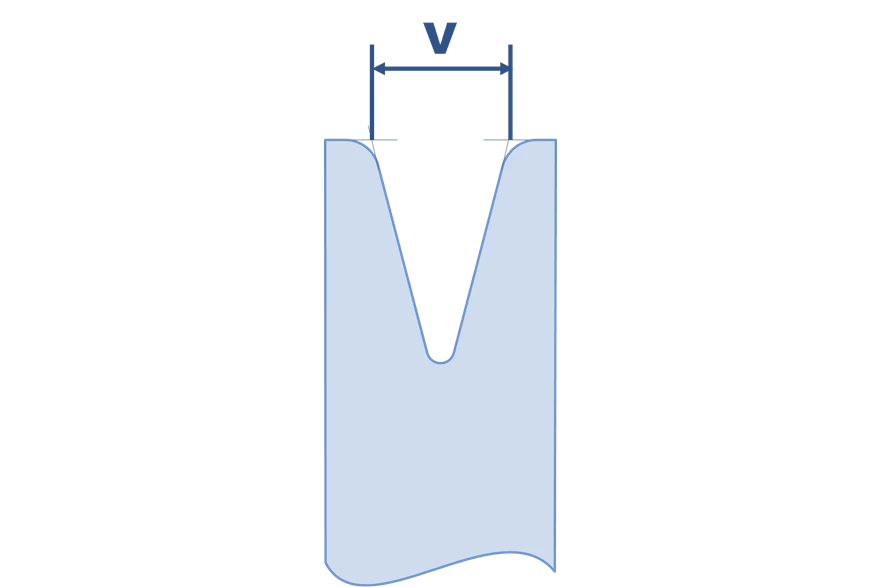

The v-die opening size affects how you use a press brake. Picking the right die opening helps you make accurate bends. It also matches the tool to the material and keeps each part high quality. Many shops follow the “rule of 8.” This means you choose a die opening size that is approximately eight times the thickness of your material. But this rule does not cover everything. Springback can change with your material and how you bend it. Look at this table:

|

Limitation |

Description |

| Rule of 8 | Makes springback too simple, so mistakes can happen |

| Springback Variability | Changes with each material and bending setup |

| Modern Methods | FEA and IPSCS can guess bend results more exactly |

If you know how die opening, bend radius, and material thickness work together, you can make better choices and improve every bend.

Press Brake V Die Opening & Bending

Press Brake Bend Radius

The press brake bend radius is one of the most important factors in any bending operation. Control this radius by choosing the right v-die opening. When you use a larger v-die opening, you get a larger press brake bend radius. If you use a smaller v-die, the press brake bend radius becomes tighter. This relationship helps you decide which die to use for each job.

- The width of the v-die opening changes the press brake bend radius.

- A larger v-die opening increases the press brake bend radius.

- A smaller v-die opening creates a tighter press brake bend radius.

- The press brake bend radius is usually about 0.156 times the v-die opening for mild steel.

Press brake bend radius also affects the bend angle you can achieve. If you want a sharp bend, you need a smaller press brake bend radius, which means a smaller v-die opening. For a gentler bend, a larger v-die opening works better. The strength of your material also plays a role. Stronger materials need a larger press brake bend radius for the same v-die opening.

Tip: Always check the press brake bend radius before you start bending. This step helps you avoid cracks and keeps your parts strong.

The rule of 8 is a common guideline in the press brake world. It says you should pick a v-die opening about eight times the thickness of your material. This rule helps you balance the press brake bend radius, springback, and the force needed for bending. For example, if your material is 2 mm thick, you should use a v-die opening of about 16 mm. This approach gives you a good press brake bend radius and helps prevent problems like cracking or uneven bends.

Material Thickness & Type

Material thickness and type have a big impact on your choice of v-die opening and the press brake bend radius. Thicker materials need more force to bend, and the press brake bend radius must be larger to avoid damage. If you try to use a small v-die opening with thick material, you may see cracks or distortion.

Here is a table that shows how material thickness affects the recommended v-die opening:

|

Material Thickness (mm) |

V-Die Opening (times thickness) |

| 3 | 6 to 12 |

| 6 | 8 |

| 12 | 10 to 12 |

The press brake bend radius should match the thickness of your material, especially for ductile metals. If you use a press brake bend radius that is too small, you risk damaging the part. For example, bending 6 mm thick steel needs a larger press brake bend radius and a wider v-die opening than bending 3 mm thick steel.

Material type also matters. Steel and aluminum usually use a v-die opening about eight times the thickness. Stainless steel, especially if it is thicker than 1/2 inch, may need a v-die opening ten times the thickness. Here is a quick reference:

|

Material Type |

Recommended Die Opening Size (times thickness) |

| Steel | 8 |

| Aluminum | 8 |

| Stainless Steel | 10 (if thickness > 1/2 inch) |

You can see that different materials and thicknesses need different v-die openings. This flexibility lets you use your press brake for many types of bends and materials. For example, if you want to bend 1/8 inch steel, you should use a 1-inch v-die opening. For 1/4 inch steel, a 2-inch v-die opening works best.

- Thicker materials need more force to bend.

- The force needed increases quickly as thickness goes up.

- The press brake bend radius should be at least as large as the material thickness for ductile metals.

Note: Always match your v-die opening to both the thickness and type of material. This step helps you get the right press brake bend radius and prevents bending defects.

By understanding how the v-die opening, press brake bend radius, and material thickness work together, you can make better choices for every press brake job. This knowledge helps you avoid mistakes and keeps your parts strong and accurate.

Consequences of Incorrect V Die Opening

Bending Defects

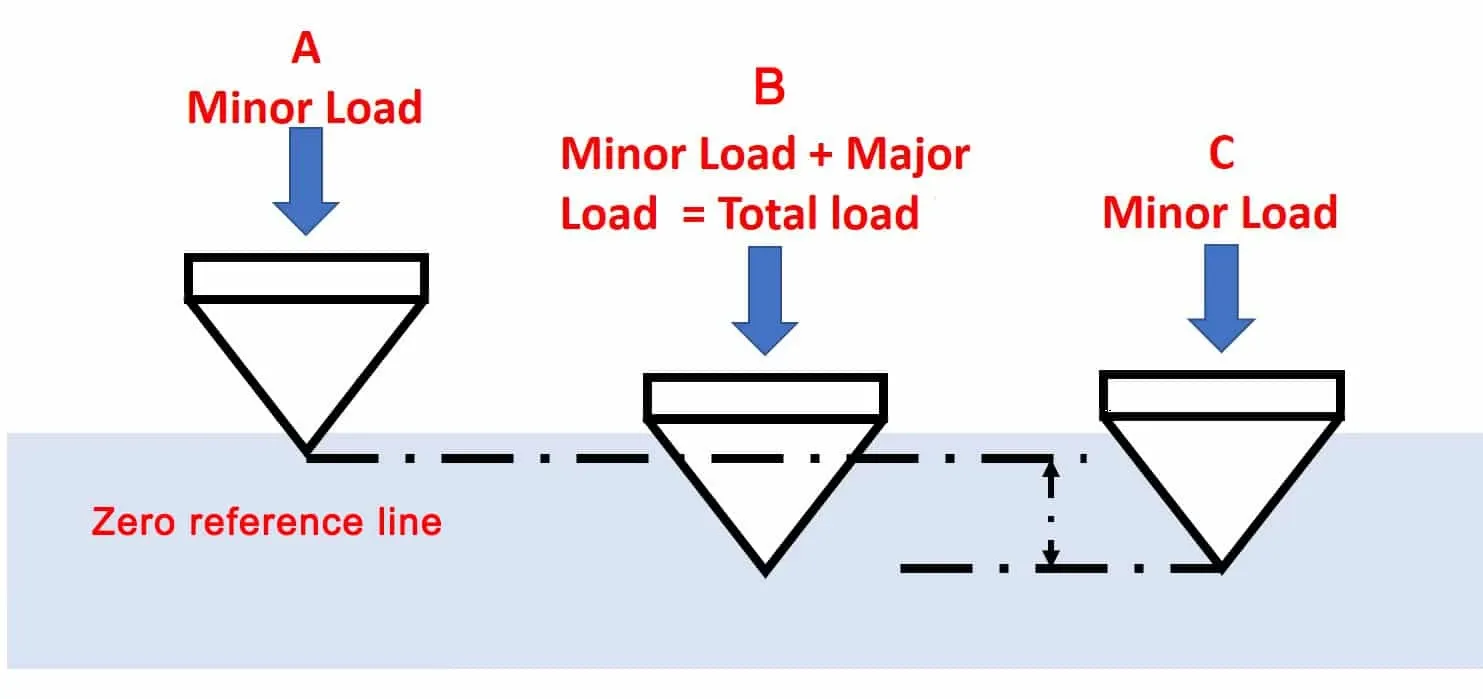

Choosing the wrong die opening for your press brake can cause many bending problems. You may see cracks along the bend line or find that the bend angle does not match your target. Sometimes, the metal may wrinkle or thin out too much. These issues happen because the material does not get enough support during bending. When you use the wrong v-die, the press brake may apply too much force, which can lead to wall thinning, wrinkling, or even springback errors. These problems make it more likely that your bends will fail.

Here is a table that shows common bending defects and their causes:

|

Symptom Identification |

Root Cause Analysis |

|

Bend angle overshoots or undershoots target |

Springback from improper v-die opening width increases internal bend radius and errors |

If you use a die opening that is too narrow, you may see cracks or inconsistent angles. A die that is too wide can make the bend radius too large, which affects the accuracy of your bends. You want to avoid these problems to keep your parts strong and reliable.

Tip: Always check your die size before bending. This step can help you avoid costly mistakes.

Tool & Material Risks

The risks do not stop at bending defects. Using the wrong die can also damage your press brake tools and materials. If you pick a die that is too small, the press brake must use more force to make the bend. This extra force can wear out your tools faster or even break them. A die that is too large can also cause problems, such as poor repeatability and tool damage.

Here is a table that explains these risks:

|

Issue |

Description |

|

Increased Bending Force |

A smaller die opening increases the force needed, which can damage tools and materials. |

| Reduced Repeatability | Incorrect die sizes make it hard to get the same bend every time. |

| Tooling Damage | Using the wrong die size can cause wear or breakage of your press brake tooling. |

You should always choose a v-die opening between 6 and 12 times the thickness of your material. This range helps you avoid material cracking, inconsistent bends, and tool breakage. If you use the right die, you can keep your press brake running longer and produce better parts.

How to Select Press Brake Die Types

Key Factors

When you pick a press brake die, you need to think about a few things. The right v-die opening helps you make strong and accurate bends. Always check what kind of material you have and how thick it is. Different materials need different dies. For example, stainless steel often needs a bigger v-die than aluminum. The bend radius you want also matters. If you want a sharp bend, use a smaller v-die. If you want a softer bend, pick a bigger v-die.

- The type and thickness of your material are very important.

- Most of the time, the v-die opening should be about eight times thicker than your material.

- Never use a v-die opening less than six times the thickness.

- The bend radius you want will help you choose your die.

- A bigger v-die opening can help stop unwanted bending problems.

Choosing the right die keeps your press brake and tools working well. This helps your machine last longer.

Industry Standards & Tips

Industry rules help you start picking the right die. There is not just one perfect v-die opening for every job. The best die depends on your material, its thickness, and the bend you need. Many people use the “rule of 8,” but you should always check your work and change things if needed.

- The v-die opening is important for making good bends.

- Always match your die to the material thickness, type, and bend radius.

- Thin materials may need sharper bends and smaller radii, so use special punches and dies.

- Hard bends may need special dies like gooseneck or hemming dies.

- The right punch and die help shape the bend and stop the material from warping.

Here is a table to help you see the differences between common press brake die types:

|

Factor |

American Precision Style |

Bevel Tang Style |

European Precision Style |

Wila Trumpf Style |

| Compatibility | Works with many machines | For newer Amada presses | Used a lot in Europe | For very precise machines |

| Precision | Good accuracy | Easy to set up | Very accurate | Super accurate |

| Ease of Use | Simple to use | Fast to install | Easy to use | Quick tool changes |

Tip: Always test your die setup before you start making lots of parts. This can help you avoid mistakes and save money.

If you follow these rules and tips, you can get better bends. Picking the right die means your parts look better, you get fewer mistakes, and your tools last longer.

Picking the right die helps you make accurate bends. The v-die opening should match your material thickness. It is usually about eight times thicker than the metal. This choice helps stop spring back and cracking. If you use the wrong die, your bend angles may change. Your parts can end up different and hard to fit together.

Tip: Adjustable dies with more than one v-die opening help you do many jobs and keep your bends correct.

The right die makes bending easier. You fix fewer mistakes and make better parts.

Choosing the correct die helps your press brake last longer. Dies made from strong materials like tool steel or carbide wear out slower. You will not need to buy new dies as often. Your machine needs less fixing, so you save money and keep working.

The right die lowers repair costs and downtime. Your press brake works better and gives good results for a long time. This matters most if you make lots of parts. The right die stops tool damage and keeps your machine in good shape.

Note: Take care of your dies and pick the right ones for each job. This helps your press brake last longer and saves you money.

|

Best Practice |

Description |

| Regular Maintenance | Check and take care of dies so they work well. |

| Operator Training |

Learn the Rule of Eight and how to change die openings. |

| Material Considerations | Pick the right die for your material to stop problems. |

You might want to pick a trusted CNC press brake tooling maker like Anhui Tooling for good results.

FAQ

What does the die opening width mean in a press brake operation?

Use the die opening width to control how the metal bends during the operation. The width affects the bend radius and the force needed. Always check the die opening width before you start any operation.

The bend radius changes how the metal reacts in each operation. A larger bend radius can stop cracks and keep the metal strong. You should match the bend radius to your sheet metal processing needs for the best results.

Multi-v dies let you switch die opening width quickly during an operation. You can bend different metal thicknesses without changing tools. This makes your forming operation faster and more flexible for sheet metal processing.

Yes, the wrong die opening width may cause cracks or weak bends in the metal. You should always pick the right width for each operation. This step helps you avoid problems in sheet metal processing.

You should look at your metal type and thickness. A good bend radius keeps the metal from breaking during operation. Always test the bend radius before starting a big job.