Press brake tools are essential components in metal fabrication, playing a crucial role in determining the accuracy, quality, and efficiency of bending operations. The performance and outcome of a press brake machine depend largely on the characteristics and specifications of the tools used. Understanding the parameters of press brake tools helps operators select the right tooling for specific bending tasks, ensuring precision and consistency while minimizing material waste and machine wear. Today I am bout to veil the secrets behind essential parameters of press brake tools, including system, angle, opening, radius, height, max load, material, and length/weight, and explains what each parameter indicates and how it affects bending performance.

Compatible Tooling System

The “system” refers to the tooling standard or interface type used by the press brake machine. Different systems determine the compatibility of press brake tools with the machine and affect setup time, tool change efficiency, and accuracy. Here are the common types of tooling systems:

European Style – Known for its high precision and quick-change capability, widely used in European markets.

American Style – Uses a flat tang, offering high strength and stability, common in North America.

Wila/Trumpf Style – Known for its high precision and quick clamping systems, offering improved repeatability and faster setup.

Selecting the correct system ensures compatibility with the press brake machine, minimizes downtime, and improves production efficiency.

Angle

The angle defines the bending angle that the tool is designed to create. It directly influences the accuracy of the bend and the final shape of the metal piece.

Types of Angles:

90-Degree Tools – Used for creating right-angle bends.

Acute Angle Tools – Designed for bending angles less than 90 degrees.

Obtuse Angle Tools – Used for bending angles greater than 90 degrees.

The bending angle is critical in determining the precision of the final product. Tools with higher accuracy in angle control reduce the need for secondary adjustments and improve overall consistency.

Opening

The “opening” refers to the width of the V-die opening. It influences the bending force required, the minimum bend radius, and the overall bend quality.

How Opening Affects Performance?

A narrower opening increases bending pressure and allows for smaller bend radii. A wider opening reduces bending pressure but may result in less precise bends.

The general rule is that the opening width should be approximately 6 to 8 times the material thickness to achieve optimal bending performance. Selecting the correct opening size ensures consistent bends without material cracking or deformation.

Radius

Radius

The radius defines the internal bend radius created by the press brake tool. It depends on the punch tip radius and the die opening size.

Factors Affecting Bend Radius

Material Type – Softer materials like aluminum require a larger bend radius to avoid cracking.

Tool Geometry – Smaller punch radii create sharper bends, but may increase the risk of material failure.

Springback – Materials tend to spring back after bending, so a slightly smaller radius may be needed to compensate.

A properly matched radius ensures that the bend maintains structural integrity and dimensional accuracy.

Height

The height refers to the overall height of the press brake tool, including both the punch and the die.

Why Height Matters?

Tool Clearance

Taller press brake tools provide better clearance, which is essential when working with complex or deep bends.

Strength and Stability

Taller press brake tools are generally stronger and more stable, which is important for handling thicker materials.

Machine Compatibility

The height must be compatible with the press brake machine’s stroke and open height capacity.

Correct tool height ensures that the press brake machine operates within its design limits, avoiding tool or machine damage.

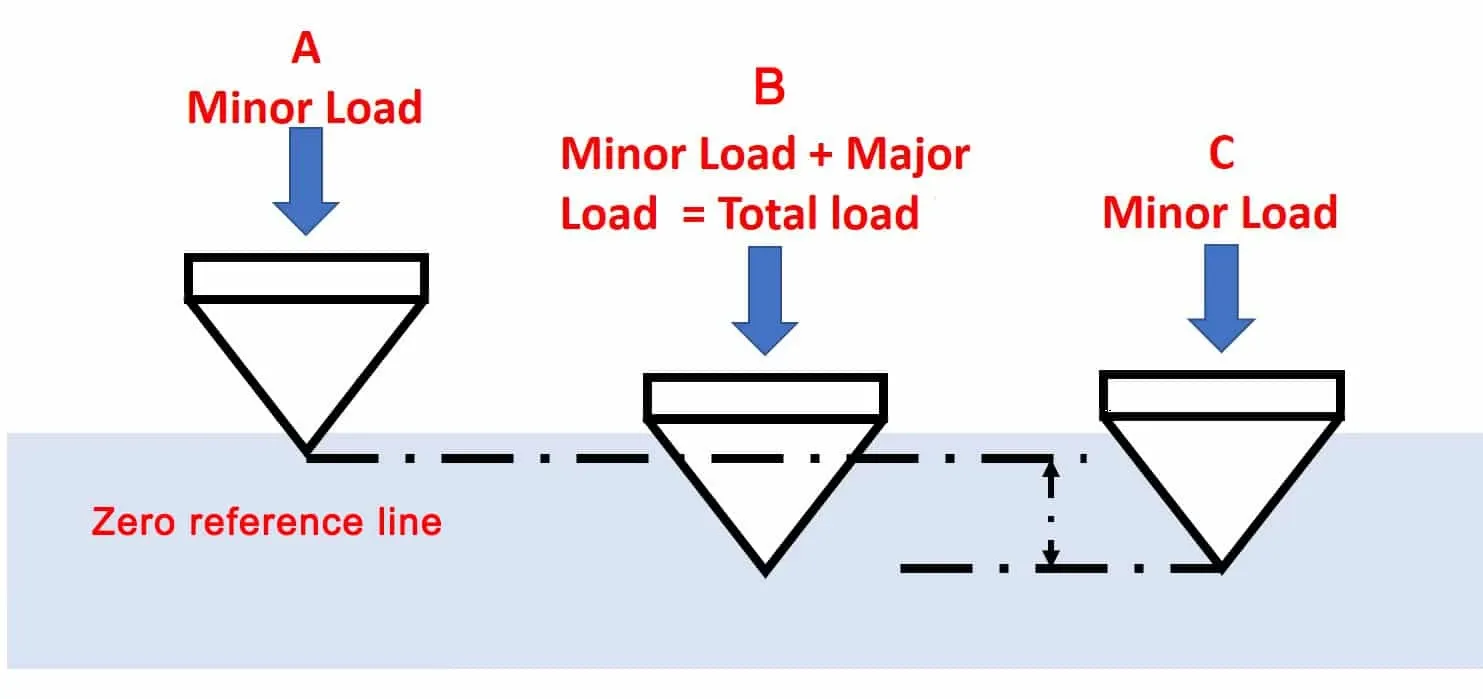

Max Load

The max load indicates the maximum pressure or force that the press brake tool can withstand without damage or deformation. It is measured in tons per meter (T/m).

Factors Affecting Max Load

Tool Material

High-strength tool steels can handle higher loads without deformation.

Design and Geometry

Wider dies and thicker punches distribute load more effectively, increasing max load capacity.

Bending Type

Air bending requires less load than bottoming or coining.

Matching the tool’s max load capacity with the machine’s tonnage and material properties prevents tool damage and extends tool life.

Material

The material stands for the type of steel or alloy used in manufacturing the press brake tool. It determines the tool’s strength, durability, and wear resistance.

Cr12 Steel – Offers high hardness and wear resistance.

42CrMo – Combines high toughness with good wear resistance, suitable for heavy-duty applications.

Carbide-Coated Steel – Provides increased surface hardness, reducing wear during high-volume production.

High-quality tool materials improve tool life, maintain dimensional accuracy, and reduce the frequency of tool replacement.

Length/Weight

The length parameter defines the overall length of the press brake tool, while the weight parameter affects handling and machine compatibility.

Length Considerations:

Short Tools – Easier to handle and ideal for creating small or complex parts.

Long Tools – Suitable for creating long, continuous bends but require more precise alignment.

Weight Considerations:

Heavier tools offer better stability but may require lifting assistance during installation. Lighter tools are easier to change and adjust but may be less stable during high-tonnage bending.

Choosing the correct length and weight ensures operational efficiency and consistent bending quality.

How to Use Press Brake Tool Parameters for Better Performance

Understanding press brake tool parameters allows manufacturers to:

✔️ Select the right tool for the material and bending angle.

✔️ Optimize bending pressure and minimize material waste.

✔️ Ensure machine compatibility and prevent tool damage.

✔️ Improve product consistency and reduce production downtime.

By carefully evaluating each parameter, manufacturers can achieve higher efficiency, reduce operational costs, and enhance the quality of the final product. For instance, choosing a punch with the correct radius and height ensures the material bends accurately without cracking, while selecting a die with the right opening size minimizes springback and improves bend accuracy.

Conclusion

Press brake tool parameters—System, Angle, Opening, Radius, Height, Max Load, Material, and Length/Weight—provide valuable insights into the performance and capabilities of the tools used in metal bending operations. Understanding these parameters helps manufacturers and operators make informed decisions, ensuring that the press brake machine performs efficiently and produces high-quality parts with consistent accuracy. By selecting the right tool specifications, manufacturers can extend tool life, improve product quality, and maximize overall production efficiency.

Radius

Radius