Every minute spent changing press brake tooling or adjusting your worn press brake can impact a company’s productivity and bottom line. One tool that has gained significant attention for its ability to streamline production processes and reduce downtime is the 4 way press brake die. Whether you are in the automotive, construction, or sheet metal industry, understanding the benefits and applications of 4 way press brake dies can help you make informed decisions that ultimately enhance your operations.

What Are 4 Way Press Brake Dies?

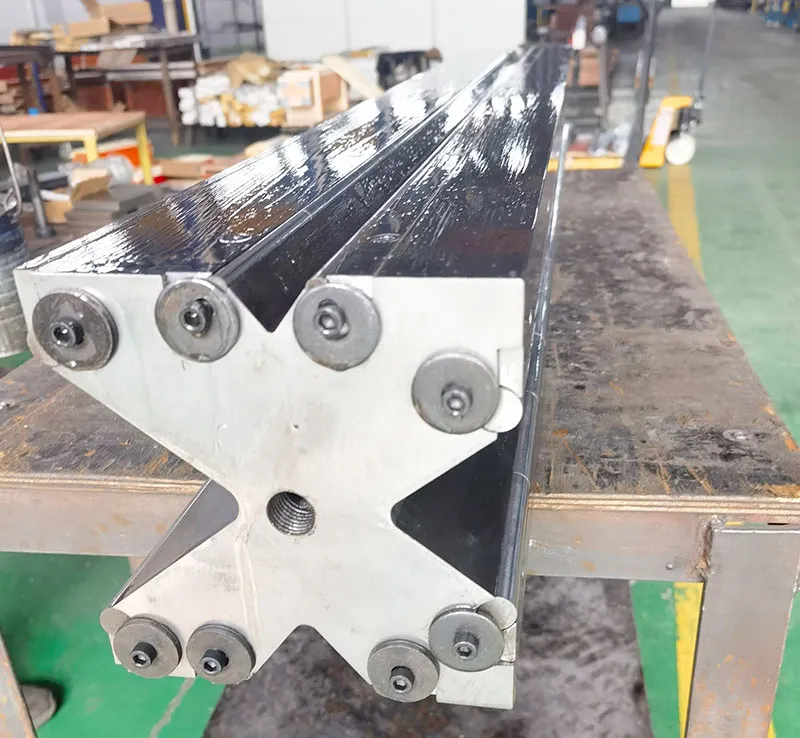

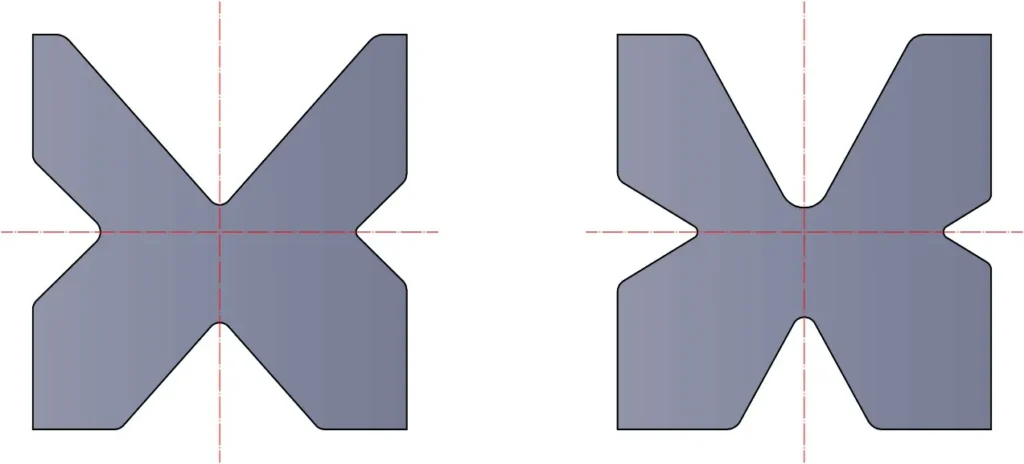

A 4 way press brake die is a type of bending die used in sheet metal forming. It is called “4 way” because it features four distinct bending options, each with its own set of V opening sizes. These dies are highly versatile, enabling users to perform multiple types of bends without having to change the die between operations. The different V openings are designed to accommodate various material thicknesses, allowing fabricators to bend a wide range of materials in a single setup.

The versatility of 4 way press brake dies is one of their most valuable features. By having four distinct bending stations on the same die, operators can easily switch between different bends based on the material type and thickness. This means that a single press brake die can handle multiple bending tasks, making it an invaluable tool for businesses looking to streamline their production processes.

Advantages of Using 4 Way Dies

One of the most significant advantages of using 4 way press brake dies is their ability to improve efficiency and reduce tool changeover time. Traditional dies require operators to change tooling whenever the material thickness or bend radius changes. This can be time consuming, especially in high volume production settings. With 4 way dies, however, the need for frequent tool changes is minimized, allowing for continuous production and less downtime.

Here are some benefits of 4 way press brake dies:

Reduced Downtime: Since 4 way dies allow for multiple bending options in a single die, operators can complete different bending tasks without switching out the die. This reduces the time spent setting up and adjusting machinery.

Cost Savings: Fewer tool changes mean fewer tools to purchase and maintain, which translates to lower operational costs in the long run.

Increased Flexibility: 4 way dies are ideal for handling a variety of material types and thicknesses. This makes them a versatile option for manufacturers working with multiple materials and a broad range of thicknesses.

Improved Productivity: With the ability to bend multiple materials and thicknesses in a single setup, operators can achieve higher throughput and quicker cycle times, leading to increased productivity.

Several industries stand to benefit from these advantages, particularly in high volume and precision metal fabrication. Companies in these sectors often need to produce parts with a variety of bends and angles. A 4 way press brake die offers a cost effective solution that enhances their operations.

Choosing the Right 4 Way Press Brake Die for Your Project

Selecting the right4 way press brake die for your specific project is critical to achieving optimal results. While the versatility of 4 way dies is a clear advantage, the key to maximizing efficiency lies in choosing the right die configuration for your materials and project requirements.

Here are some essential factors to consider when selecting a 4 way die:

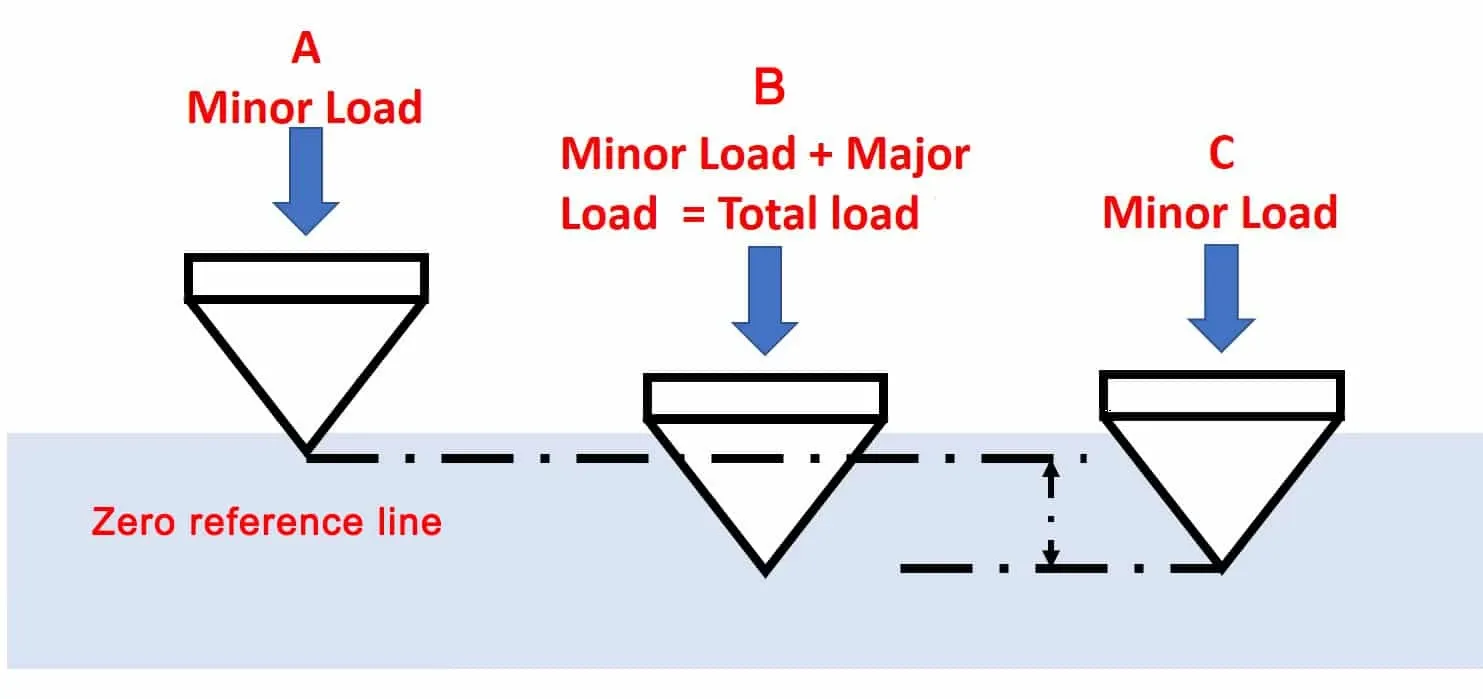

Material Thickness

Each V opening on a 4 way press brake die is designed for a specific material thickness. It is important to match the thickness of the material you are working with to the appropriate V opening. If the material is too thin for the V opening, it may result in poor bending quality or a lack of precision. Conversely, if the material is too thick for the V opening, the die may not provide enough bending force, leading to uneven bends or tool wear.

Bend Radius

The bend radius refers to the internal radius of the bend. Choosing the right bend radius is essential for ensuring that the material does not crack or deform during the bending process. A 4 way die offers multiple bend radius options, allowing for a wider range of bending tasks to be performed in a single operation.

Material Type

Different materials, such as aluminum, stainless steel, or carbon steel, may require different bending techniques and forces. 4 way dies are versatile enough to accommodate various materials, but it is essential to ensure that the V opening and bend radius are compatible with the material you are working with.

Die Material and Durability

The material of the die itself plays a crucial role in its longevity and performance. High quality dies made from durable materials, such as tool steel, offer superior wear resistance and can handle high frequency bending tasks without losing their shape or functionality.

Applications of Press Brake 4 Way Dies

4 way press brake dies are used in a variety of applications, particularly in industries where high precision and flexibility are required. Here are some common scenarios where 4 way dies excel:

Bending Multiple Material Types in a Single Setup

In industries like automotive manufacturing, where components made of different materials are required, a 4 way press brake die can bend multiple types of metals in a single pass. This eliminates the need for changing dies between different material types, which improves overall efficiency.

High Volume Production

4 way press brake dies are particularly beneficial in high volume production environments. For instance,construction companies often need to produce metal parts with precise bends for framing, supports, and panels. By using a 4 way die, these companies can increase throughput and reduce downtime, leading to more efficient production processes.

Sheet Metal Fabrication

Sheet metal fabricators often work with materials of varying thicknesses and require a range of bending angles. With a 4 way press brake die, fabricators can bend different thicknesses and achieve multiple angles without switching tools. This leads to faster production and greater flexibility in handling different projects.

Custom and Complex Bending Tasks

For businesses that require custom bending tasks, 4 way press brake dies provide the flexibility to perform complex and precise bends with ease. The ability to change between four different V openings without changing the die is especially useful when working on intricate designs or low volume, custom parts.

Conclusion

In conclusion, the use of 4 way press brake dies offers significant advantages in terms of productivity, efficiency, and cost effectiveness. By reducing tool changeover time and increasing flexibility, these dies help manufacturers streamline their production processes. Industries such as automotive, construction, and metal fabrication are among the primary beneficiaries of this innovative technology.

When selecting a 4 way die, it is important to consider factors such as material thickness, bend radius, and the types of materials you will be working with. By making the right choice, you can maximize the performance of your press brake and enhance your production efficiency.

At Anhui Tooling, we specialize in high quality 4 way press brake dies designed to meet the demands of modern manufacturing. Our products are built to provide superior performance, long lasting durability, and cost effective solutions for businesses of all sizes. Contact us today to learn more about how our 4 way press brake dies can enhance your operations and help you achieve greater productivity.