Introduction

Press brake tooling is at the heart of precise metal bending. Each tool type—whether it’s a flattening die or a bottom die—plays a crucial role in determining the accuracy, durability, and efficiency of the bending process. Anhui Tooling, which specializes in high-quality press brake tools, understanding these components allows for better serving the diverse needs of the metal fabrication industry. Here we go to learn about the essentials of press brake tooling, covering everything of bottom tools-press brake die types and design elements to specific tool features and selection tips to ensure the best results in any bending operation.

Press Brake Tools: The Essentials

Press brake tools refer to the various press brake punches and dies used to bend metal sheets. These tools form the backbone of press brake and are designed to create bends, folds, and other shapes with precision and repeatability. Selecting the right press brake tools not only improves product quality but also maximizes press brake efficiency and longevity.

Why the Right Tools Matter

Anhui Tooling‘s collection of press brake tools is crafted for high performance and durability, whether in high-volume production or custom jobs. Each tool undergoes rigorous testing to ensure it meets the required standards for precision, reducing waste and maximizing productivity.

Press Brake Tooling Dies: Types and Functions

Press brake dies come in various forms, each serving a unique function in metal forming operations. Here’s an overview of the primary die types and their applications:

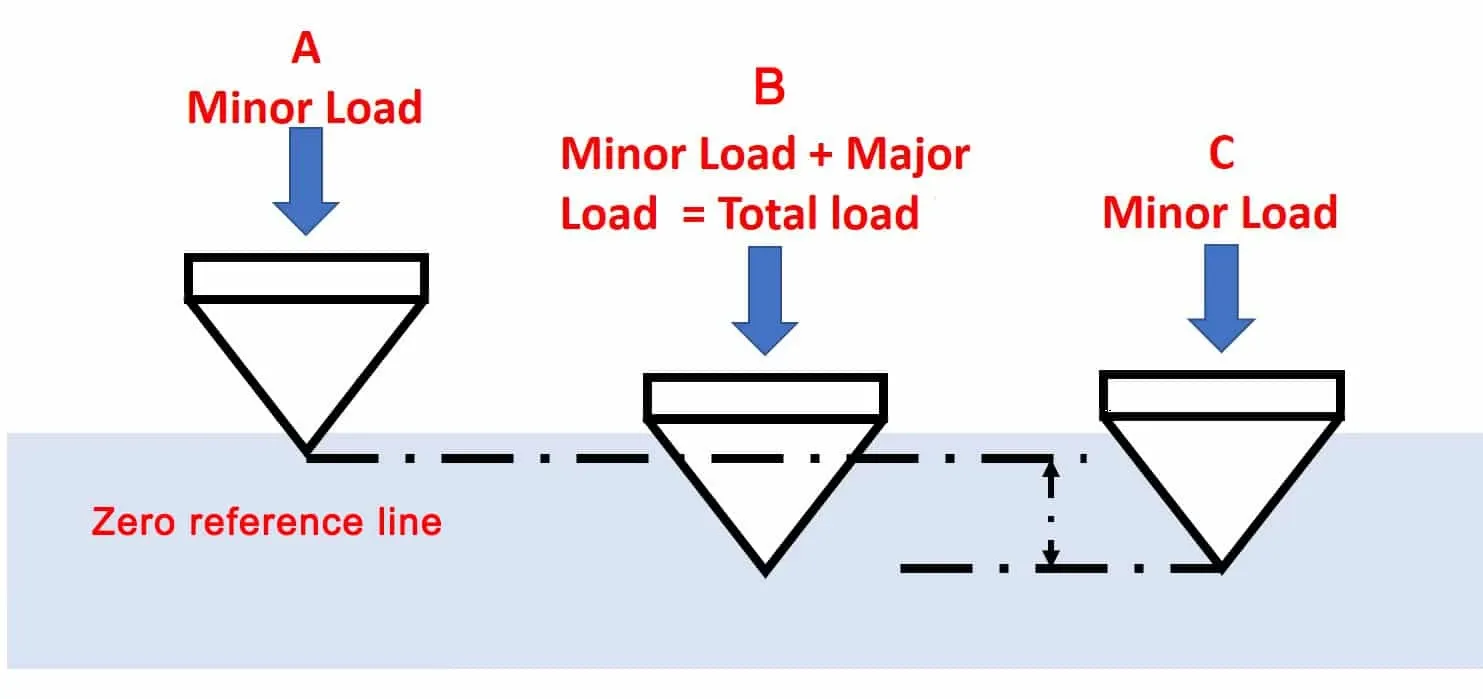

Air Bending Dies: Allow for flexible bending angles by controlling the punch’s depth. They require less force, reducing tool wear.

Bottoming Dies: Used for bending where the material makes full contact with the V opening, providing precise angles but with less flexibility in bend angles.

Coining Dies: Use higher pressure to create precise bends with minimal spring-back, making them suitable for high-precision applications.

Selecting the Right Die Type

Each die type has a specific purpose, and understanding these can help optimize forming operations. Anhui Tooling provides a broad selection of dies designed to meet diverse metalworking needs, ensuring precision and repeatability for every project.

Press Brake Flattening Dies: Ensuring Accuracy and Flatness

Flattening dies play a vital role in applications that require flat surfaces. These dies apply additional pressure after the initial bend, removing any spring-back and ensuring the part remains flat and true to the desired shape.

Applications of Flattening Dies

Flattening dies are commonly used in industries with strict flatness requirements, such as aerospace and automotive sectors. Anhui Tooling’s flattening dies are engineered to deliver consistent results, enhancing quality and reducing the need for post-processing adjustments.

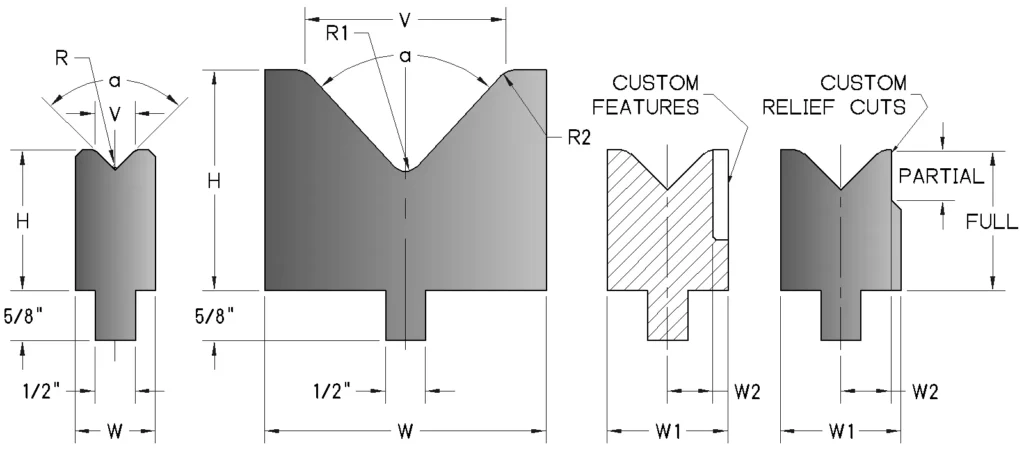

Press Brake Die Design: The Foundations of Precision

The design of a press brake die significantly affects the quality of the bends it produces. Key design elements include the angle, material composition, and overall geometry of the die.

Optimizing Workflow with Custom Die Designs

Custom die designs can enhance efficiency and meet specific operational needs, especially for unique or high-volume projects. Anhui Tooling’s engineering team offers custom die designs tailored to client specifications, ensuring compatibility and optimal performance in diverse applications. By reducing setup times and tool changes, custom dies can streamline workflows and increase productivity.

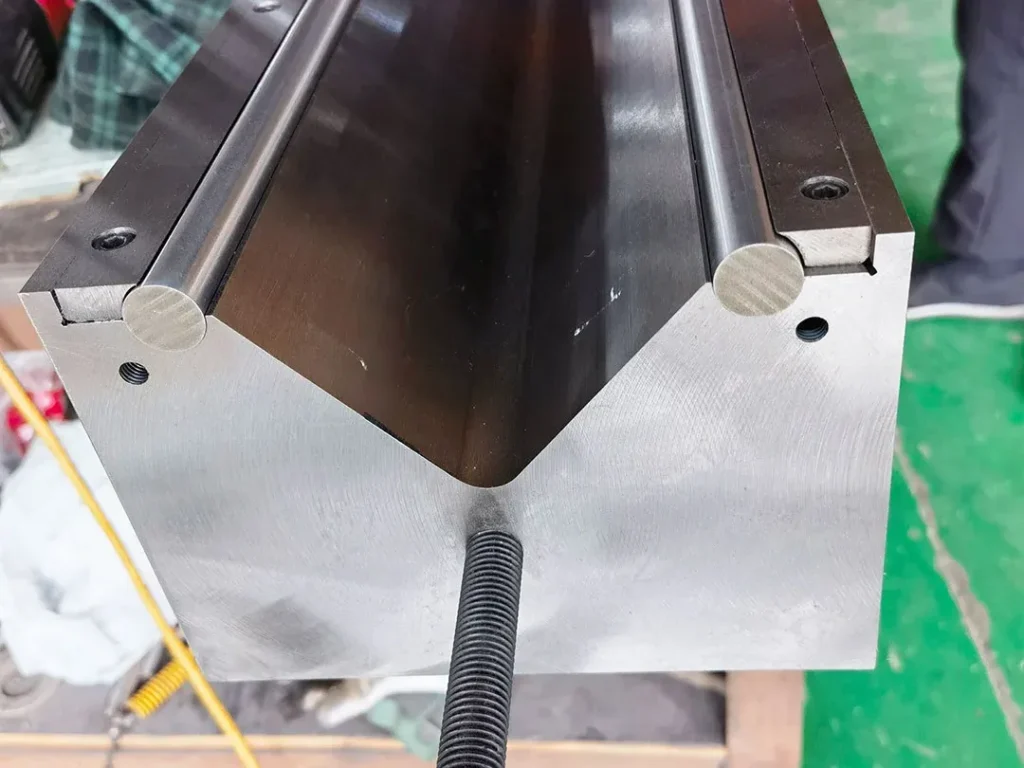

Press Brake V Die Opening: Precision in Bending

The V die opening is an important factor in determining the bend radius and angle. This opening affects how the metal is shaped and can influence the overall precision of the part.

Choosing the Right V Die Opening

Selecting the appropriate V die opening depends on the material thickness and the desired bend radius. A larger V opening is best for thicker materials, while a narrower opening is suitable for precision bends in thinner materials. Anhui Tooling’s range of V dies allows operators to fine-tune their press brakes for consistent and accurate bends, no matter the material or thickness.

Press Brake Die Selection: Factors to Consider

Selecting the right die involves considering the material, thickness, desired bend angle, and tonnage capacity. Proper die selection helps extend the lifespan of the tooling, minimizes wear, and reduces machine stress.

To ensure longevity, it’s essential to adhere to maintenance schedules, avoid overloading, and match the die type to the material and bend requirements. Anhui Tooling’s press brake dies are crafted from high-grade materials that provide durability, reducing the need for frequent replacements and keeping production lines running smoothly.

Press Brake Forming Dies: Different Types for Different Applications

Forming dies are specialized tools designed for specific applications, such as hemming or curling. These dies help create intricate shapes and are often used for custom manufacturing requirements.

Hemming Dies: Used to fold metal onto itself, typically for reinforcing edges or creating safe, smooth surfaces.

Curling Dies: Shape metal edges into curved profiles, often used in automotive and appliance manufacturing.

Choosing the right forming die ensures efficiency and high-quality results in custom operations. Anhui Tooling offers an array of forming dies that cater to a variety of bending and shaping requirements, enabling manufacturers to produce unique parts with minimal error.

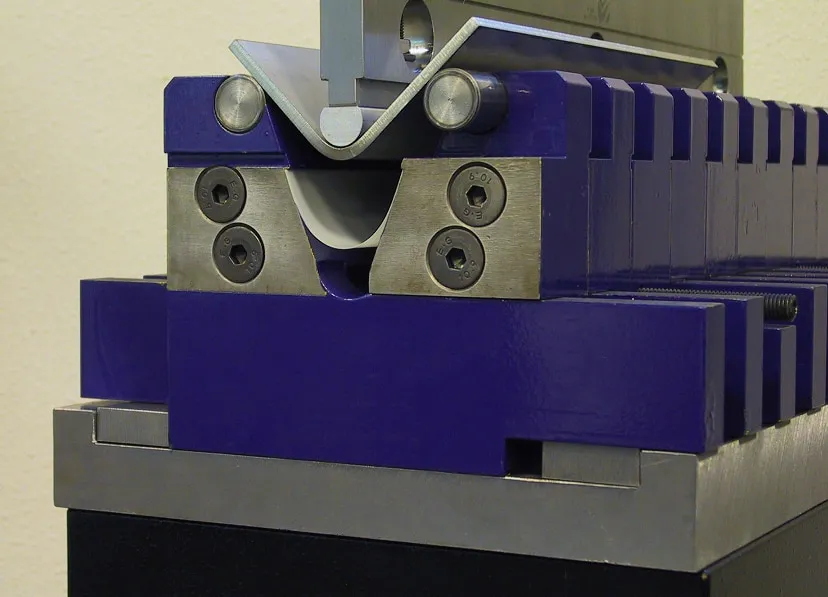

Press Brake Bottom Die: Essential Support in the Bending Process

The bottom die supports the material during bending and significantly affects the shape of the bend. Selecting the correct bottom die type, such as a multi-V or a four-way die, is crucial for achieving the desired bend angle and radius.

Matching Bottom Dies with Top Tooling

For consistent results, the bottom die should match the top tooling in both size and shape. Anhui Tooling provides a wide selection of bottom dies, including reversible options that allow operators to achieve multiple bend configurations with a single die. This versatility is especially useful in high-volume production settings.

Press Brake Tooling Set: A Complete Solution for Large-Scale Operations

Press brake tooling sets offer a comprehensive solution for manufacturers handling diverse bending requirements. These sets typically include a range of punches, dies, and other essential tools that can accommodate various applications and material types.

Cost-Effectiveness of a Tooling Set

Investing in a complete press brake tooling set can be cost-effective for large-scale production, reducing the need for frequent tool purchases and minimizing downtime for tool changes. Anhui Tooling’s tooling sets are designed to be versatile and durable, providing manufacturers with a reliable solution that meets their long-term needs and boosts overall efficiency.

Conclusion

Press brake tooling is essential for precision metal bending. Understanding the different tooling options—whether it’s selecting the right V die opening, choosing the best die design, or investing in a comprehensive tooling set—can make a significant difference in the quality and efficiency of bending operations. Anhui Tooling offers a full spectrum of high-quality press brake tooling solutions, crafted to meet the demanding requirements of today’s metal fabrication industry. By choosing the right tooling from Anhui Tooling, manufacturers can ensure precise bends, improve productivity, and extend the lifespan of their press brake machines.

For more information on how our tooling solutions can elevate your bending operations, visit Anhui Tooling’s website today. Our team of experts is ready to help you select the perfect tools for your unique needs, ensuring your press brake operations deliver the highest quality results every time.