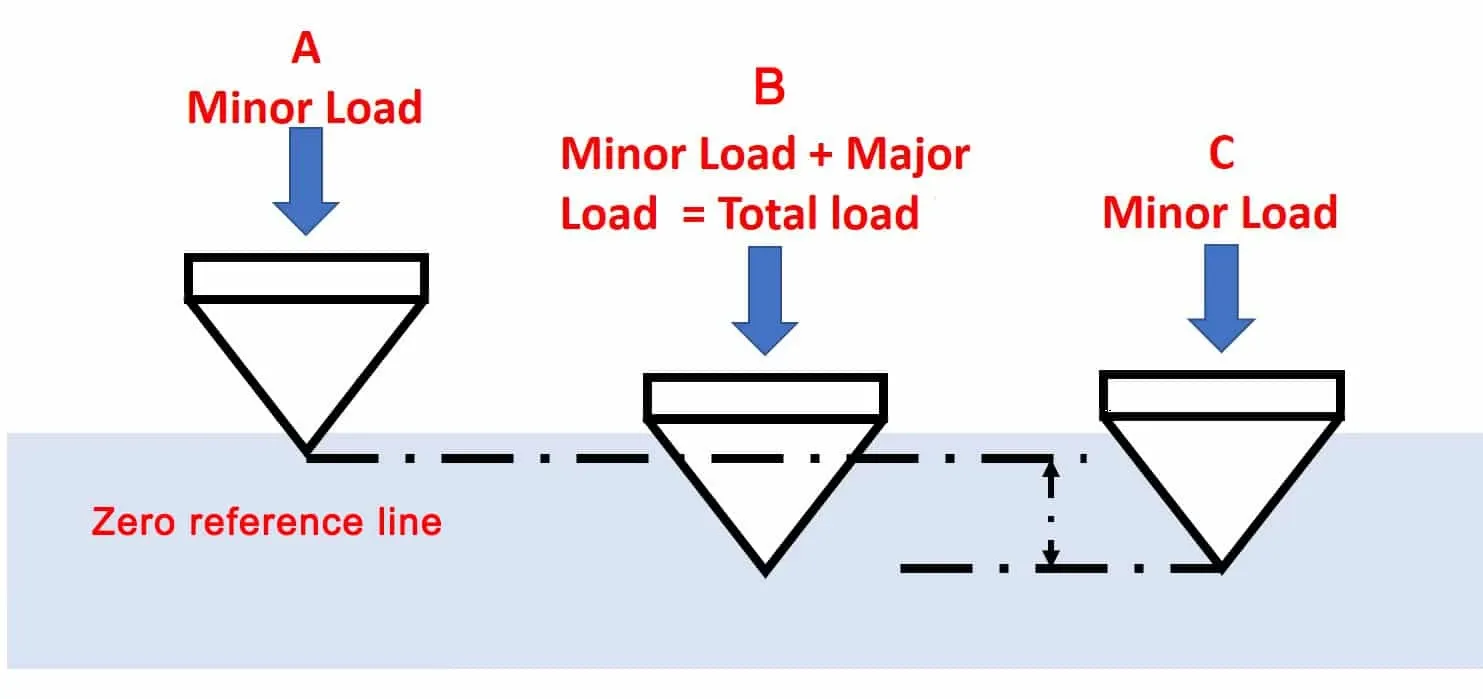

Choose the right punches and dies

There are different types of punches and dies, and selecting the correct matching punches and dies for bending is crucial to improve accuracy and efficiency.

Standard-size tooling is more convenient to replace, as the design of tooling parts with standard dimensions is consistent.This eliminates the need to make too many adjustments when replacing the punches and dies, as these toolings are kept in the same position for easy replacement.

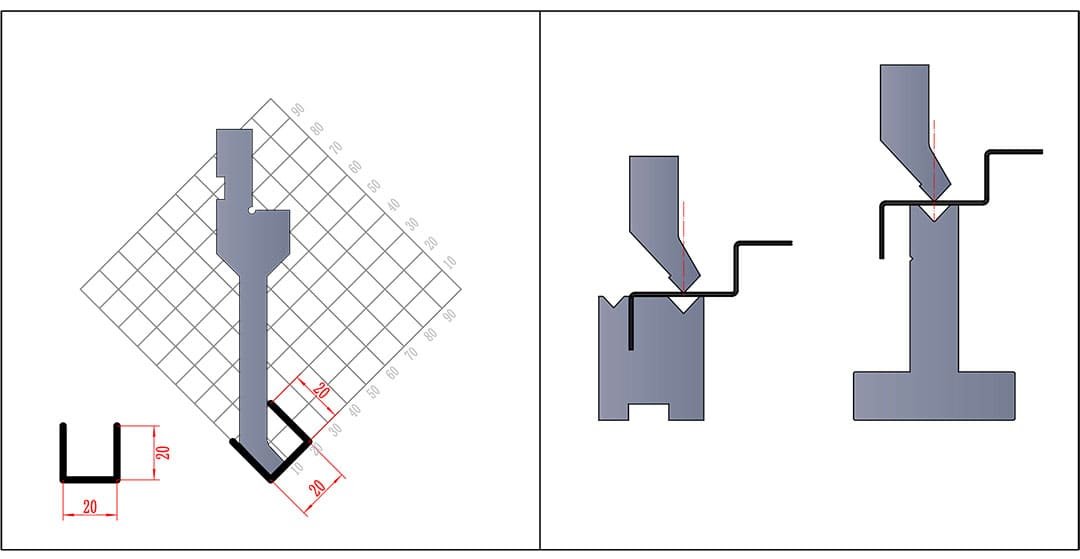

Tools length segmentation

Die segmentation can facilitate the bending process of various-sized workpieces.Press brake toolings require very high accuracy, particularly the accuracy of punch tips and die shoulders, as these parts will directly contact the sheet metal during bending.Punches and dies with high precision can reduce adjustments in the installation process.

General Press Brake Tools

General standard tools can be found in our website catalog. You only need to make a choice based on the cross-section and your product. The punch mainly considers the installation method and workpiece avoidance. The lower die needs to consider the plate thickness, V-groove size and installation method. There are many different styles of tooling for press brakes. Choosing the style and design that is compatible with the press brake you have. Refer to the press brake manufacturer manual to find out the correct tools for your machine.

Technical Support

The professional tools technical support for customers workpiece bending, Self-centering 2v, 1v, multi-v dies, gooseneck punch, standard punch, radius tools, hemming tools, special tools, crowning table, shearing baldes, die holder, clamp tools and others.

Modification the tang of punch for suitable with the customer’s machine.

Modification the V die opening according to the customer’s requirement.

Making press brake tools for customer’s bending easily.

Marking the segments size according to customer’s request.

We are 24h online, any inquiry or sales-after will solve for you asap.

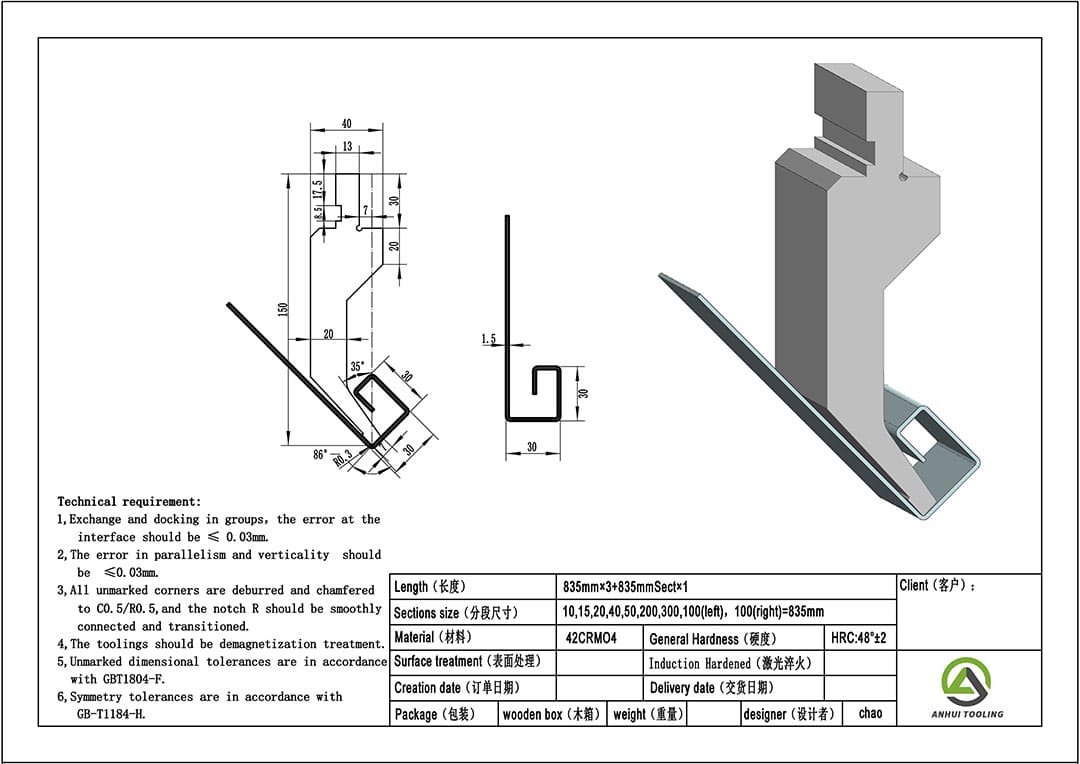

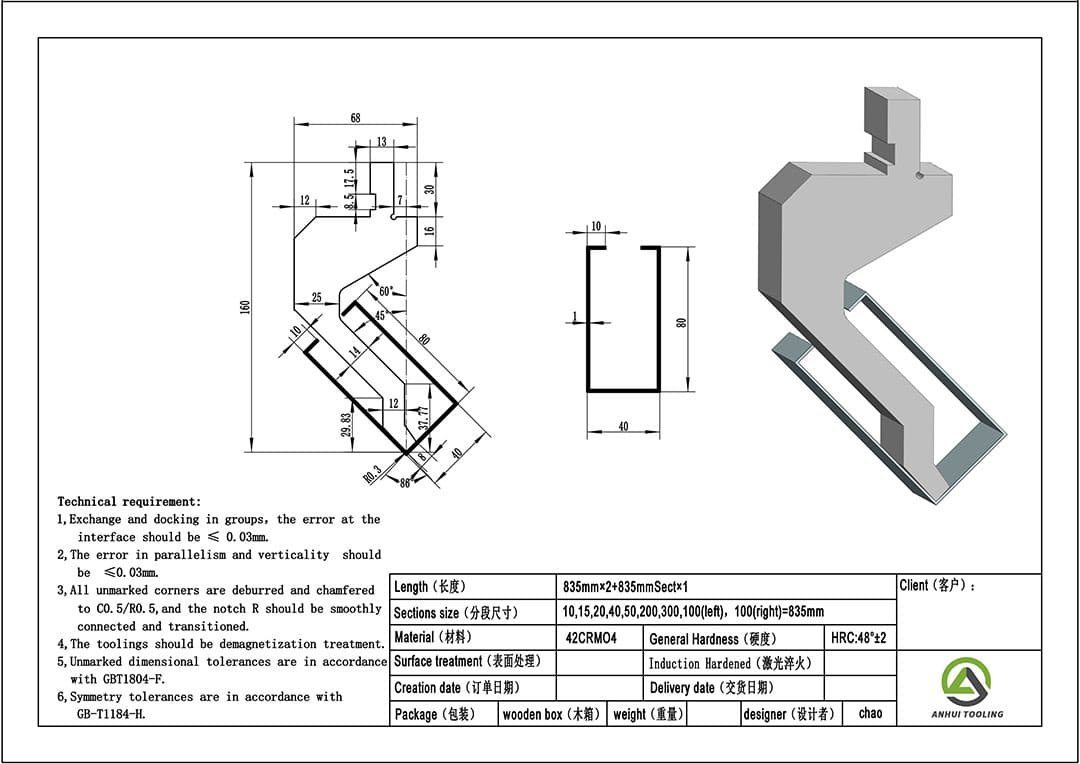

Custom Press Brake Tooling

There are quite a few standard-made options for press brakes available. These options are available quickly and can be utilized for many common bends. However, there are instances, such as large part runs or projects with unique specifications, where custom press-brake tooling is the answer. Fortunately, we offer single- and multiple-hit forming tools in a wide variety of tooling styles and quality grades to maximize your forming efficiency. Our professional staff can analyze your part and recommend custom tooling or the reworking or resurfacing of existing dies.

How to custom press brake tooling?

1.please provide the complete drawing of product and details of bendinq.like:Radius internal and extenal shape size tolerance and so on.

2.The material and thickness of bending.

3.The requirements for bending scratch.

4.The model of press brake machine.like:Pressurecrowning table length, the tang of punch.

5.Others.